PCB Manufacturing & SMT Services: Your Direct Source Factory

Focus Keyphrase: PCB Manufacturing

Secondary Keywords: Printed Circuit Board Assembly, PCB Fabrication, Industrial PCB Production.

In today’s fast-paced electronics industry, securing a partner who handles the entire lifecycle—from PCB Fabrication to final assembly—is the key to success.

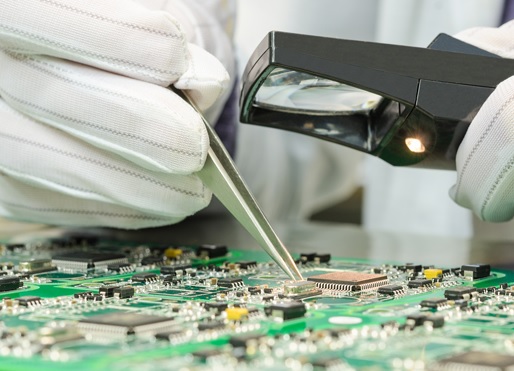

SMT (Surface Mount Technology) is just one part of the puzzle. To ensure true reliability, you need a comprehensive PCB Manufacturing partner who controls every layer of the process. As a direct source factory, CtrlPCB integrates bare board production with high-precision Printed Circuit Board Assembly, providing a seamless “One-Stop” solution for global clients.

Why Choose In-House PCB Manufacturing?

Unlike brokers who outsource your files to different shops, we operate a fully integrated facility. This means we handle both the PCB Fabrication (making the bare board) and the assembly under one roof.

Our Source Factory Capabilities:

-

Industrial PCB Manufacturing: Specialized processes for high-reliability industrial controls, automotive, and medical devices.

-

Advanced SMT Lines: Equipped with high-speed mounters for complex PCB Board designs.

-

Traceability: From the raw copper laminate to the final resistor, every step is tracked in our system.

By working with a direct Printed Circuit Manufacturer, you eliminate communication gaps. If there is a DFM issue with your layout, our fabrication engineers talk directly to our assembly engineers to fix it instantly.

Full-Spectrum Printed Circuit Board Assembly

We don’t just assemble simple boards; we handle complex technologies. Our Printed Circuit Board Assembly services cover:

-

Prototype to Mass Production: Flexible scheduling for quick-turn samples and high-volume runs.

-

Complex Components: Expertise in BGA, QFN, and fine-pitch Electronic Components.

-

Mixed Assembly: Combining SMT precision with robust THT (Through-Hole) soldering.

-

Double-Sided PCB Board: Capable of populating top and bottom sides for high-density applications.

Whether you need a simple LED driver or a multi-layer Industrial PCB, our standardized production capability ensures consistency.

Quality Control in PCB Fabrication & Assembly

Quality starts before the components hit the board. Our integrated quality system covers both PCB Fabrication and assembly:

-

IQC (Incoming Quality Control): Rigorous checking of raw laminates and Electronic Components.

-

SPI & AOI: Automated inspection of solder paste and component placement.

-

X-Ray Inspection: Essential for verifying BGA soldering quality.

-

Functional Testing: We power up your finished Printed Circuit Board to ensure it works in the real world.

Transparent Manufacturing: See It Yourself

We believe in radical transparency. You are welcome to audit our PCB Manufacturing facility at any time.

-

On-Site Visits: Walk through our copper plating lines and SMT workshops.

-

Video Audits: For overseas clients, we offer live video tours of the production floor.

-

Process Verification: Review our certifications (ISO 9001, IATF 16949) and quality records.

🚀 Start Your Project with a Direct Manufacturer

Stop managing multiple vendors. Partner with a single PCB Manufacturing source that handles everything from fabrication to assembly.

Ready for a Quote?

-

Submit Files: Send your Gerber and BOM for a comprehensive evaluation.

-

Technical Review: Our engineers will optimize your design for Industrial PCB Manufacturing.

👉 [Get Your PCB Manufacturing Quote]