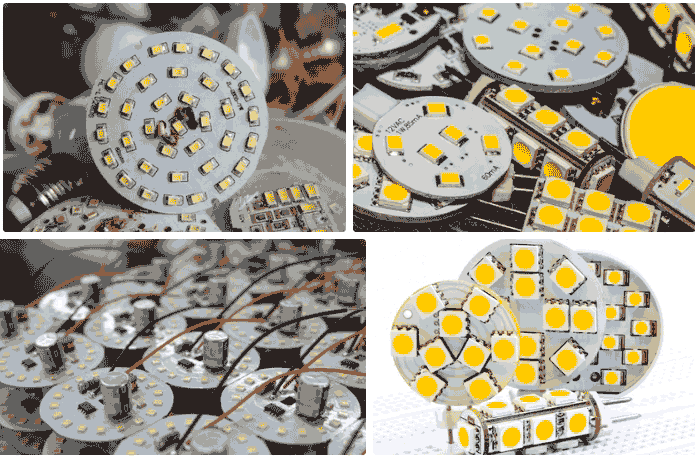

LED PCB

- LED Printed Circuit Boards: A Foundation for Efficient Lighting Technology

- Industry Applications of LED PCBs

- Advantages and Benefits of LED PCBs

- How to Choose the LED PCB

Light-emitting diodes (LEDs) are rapidly becoming one of the most popular lighting technologies across various industries due to their energy efficiency and long lifespan. Unlike traditional light bulbs, LEDs are solid-state lighting devices that convert electrical energy into light using a semiconductor. This enables LEDs to use up to 80% less energy and last up to 25 times longer than conventional lighting solutions. LEDs are also favored for their small size and environmentally friendly nature.

At the core of LED technology is the printed circuit board (PCB), which plays a crucial role in supporting and optimizing the performance of LEDs. PCBs are thin boards made from materials such as fiberglass or metal, designed to electrically connect electronic components. For LEDs, PCBs provide both physical support and an efficient pathway for heat dissipation. This is essential, as excessive heat can degrade LED performance and shorten its lifespan.

One of the key characteristics of LED PCBs is their ability to handle the high amount of heat generated by the LEDs. Metal-core PCBs, especially those made from aluminum, are commonly used in LED applications for their superior heat dissipation properties. These PCBs contain a thin layer of thermally conductive dielectric material, which helps transfer heat away from the LEDs more effectively than traditional PCBs.

SMD (surface-mounted device) packaging is now the most widely used form in LED applications. Since the light output of a single LED component is limited, multiple LEDs are often used in a single fixture to achieve the desired brightness. The PCB serves as the foundation to electrically connect these components, ensuring optimal performance and reliability.

In conclusion, LED PCBs are engineered to provide the necessary heat dissipation, electrical connections, and durability required for high-performance lighting systems. Their role is pivotal in making LED technology a sustainable and efficient solution for modern lighting needs across various industries.

LED PCBs are widely used across various industries, driven by the increasing popularity of LED technology for its energy efficiency, compactness, and versatility. Below are some of the most prominent industry applications:

- Consumer Lighting: LED PCBs are commonly used in consumer lighting products, including flashlights, lanterns, lamps, spotlights, and solar-powered lights. Their ability to offer bright, energy-efficient lighting with a long lifespan makes them ideal for everyday use.

- Consumer Electronics: In consumer electronics, LED PCBs are integral to devices such as smartphones, tablets, computers, and televisions, where they serve as displays and indicators. Aluminum-based LED PCBs are especially valued for their excellent heat dissipation, essential for heat-sensitive electronic components.

- Telecommunications: The telecommunications industry relies on LED indicators and displays due to their durability and long life. Much of the equipment used in telecommunications generates significant heat, making aluminum PCBs a crucial component for managing thermal loads effectively.

- Automotive: LED PCBs play an essential role in automotive lighting systems, including headlights, brake lights, and indicator lights. Their durability and ability to withstand harsh environmental conditions make them ideal for automotive applications, both inside vehicles and in external traffic signals.

- Medical Industry: Medical equipment, such as surgical lighting tools and examination lights, often uses LED PCBs for their durability and heat management. Additionally, medical imaging and scanning technologies incorporate aluminum PCBs to ensure accurate and reliable performance, even in high-demand environments.

- Architectural Lighting: LED PCBs are widely used in architectural lighting applications, including dynamic lighting for bridges, landmarks, and large installations. These PCBs enable vibrant, customizable lighting solutions, offering both aesthetic appeal and functional illumination.

- Display Technologies: Digital signage and display systems, such as billboards and advertising screens, often utilize LED PCBs. These boards provide bright, eye-catching visuals that are essential for marketing, enhancing brand recognition and delivering clear information in public spaces.

- Horticultural Lighting: In agriculture, LED PCBs are used to optimize light spectra for plant growth, promoting photosynthesis and increasing crop yields. Their energy efficiency and ability to deliver precise light wavelengths make them valuable tools in controlled-environment farming.

- Computing: LED PCBs are increasingly common in computing devices, where they are used in displays and indicator lights. Aluminum PCBs, known for their superior heat dissipation, are also implemented in power supplies and CPU boards to manage the thermal sensitivity of components.

LED lighting, combined with LED PCBs, offers numerous advantages that make them highly sought after across various industries. These benefits stem from the core strengths of LED technology and the engineering advancements of printed circuit boards. Below are some of the key advantages:

Reduced Power Consumption: LEDs are highly energy-efficient, consuming at least 75% less energy than incandescent bulbs. According to the U.S. Department of Energy, widespread adoption of LEDs could save up to 348 terawatt-hours of electricity by 2027, equivalent to approximately $30 billion in electricity costs. This significant reduction in power usage makes LEDs ideal for energy-conscious applications.

Longer Lifespan: LED lights boast an impressive lifespan of around 25,000 hours—25 times longer than incandescent bulbs. This extended lifespan reduces the frequency of replacements, leading to lower maintenance costs and increased convenience, especially in applications that require continuous operation.

Higher Efficiency: Traditional incandescent bulbs emit about 90% of their energy as heat, while LEDs produce very little heat, making them much more efficient at converting electrical energy into light. Furthermore, LEDs emit light in a specific direction, eliminating the need for reflectors and ensuring that more light reaches the desired area, reducing waste.

Compact Size: LEDs are much smaller than traditional lighting options, enabling their use in compact devices such as smartphones, as well as larger applications like traffic signals and floodlights. Their versatility allows manufacturers to integrate LEDs into a wide variety of products and spaces.

Environmentally Friendly: LED lights are free of toxic materials like mercury, which are commonly found in other types of lighting. This makes LEDs safer to use, easier to dispose of, and more environmentally friendly. Additionally, their reduced power consumption lowers greenhouse gas emissions linked to electricity production.

Heat Dissipation: One of the standout features of aluminum-based LED PCBs is their superior heat dissipation. LEDs generate a considerable amount of heat, and excessive heat can damage electronic components or reduce their lifespan. Aluminum PCBs provide excellent thermal transfer, ensuring that heat is efficiently conducted away from LEDs, allowing them to operate at optimal performance levels for longer periods.

Durability and Reliability: Aluminum LED PCBs are more durable compared to those made from materials like fiberglass or ceramic. They are resistant to shock, vibration, and damage, making them suitable for use in harsh environments, such as automotive, industrial, and outdoor lighting applications.

Cost-Effectiveness: Aluminum is abundant and relatively easy to refine, making it a cost-effective material for PCB manufacturing. Additionally, aluminum PCBs eliminate the need for more expensive thermal management systems, such as heat sinks, thereby reducing overall production costs while still offering reliable performance.

Lightweight: Aluminum LED PCBs are lightweight, making them easy to handle, transport, and install. This is particularly advantageous in automotive and aerospace applications where weight is a critical factor.

Customizable Designs: LED PCBs offer a high degree of design flexibility. Manufacturers can customize the shape, size, and materials of the PCB to meet specific lighting needs. Additionally, by integrating different LED components with varying color temperatures or colors, the desired lighting effects can be easily achieved. This versatility extends to the ability to create custom lighting solutions for architectural, automotive, and consumer electronics applications.

Rapid Lighting: LEDs illuminate instantly when powered, requiring no warm-up time. This instant-on capability is beneficial in applications where immediate lighting is required, such as traffic signals, emergency lighting, and automotive headlights.

Environmental and Economic Benefits: The combination of low power consumption, longer lifespan, and recyclability of aluminum makes LED PCBs environmentally friendly. They not only help reduce waste and lower carbon footprints but also contribute to cost savings over time due to reduced energy bills and maintenance costs.

Wide Range of Applications: From consumer electronics and automotive lighting to architectural displays and horticultural lighting, LED PCBs are highly versatile. Their compact size, durability, and efficiency make them suitable for a wide range of applications, including medical equipment, traffic systems, and industrial lighting.

1. Material Selection:

The choice of LED PCB manufacturing material is crucial for meeting the specific requirements of your LED application:

- Aluminum PCB: Aluminum PCBs are the go-to option when heat dissipation is a priority. LEDs generate significant heat during operation, and aluminum provides excellent thermal conductivity, helping to keep temperatures manageable.

- Copper PCB:Copper substrate is a conductive material, has good electrical properties, can ensure the normal operation and brightness of LED lamp beads.

- Ceramic PCB:The thermal conductivity of the ceramic PCB is better, and the thermal expansion of the chip is more matched, so the application of the ceramic substrate in the LED lamp bead can achieve better thermal conductivity.

- FR4 PCB:If the requirements are not high, FR4 PCB is also a common LED PCB material

- CEM1 or CEM3 PCB: If cost-saving is a major concern and your application doesn’t require intensive heat management, CEM1 or CEM3 materials might be suitable alternatives. These materials are more affordable but may offer less efficient thermal dissipation.

2. PCB Thickness:

The thickness of the PCB plays a role in the mechanical strength and durability of the board:

- Typical Thickness Range: LED PCBs usually range between 0.8mm and 3.0mm in thickness.

- Thicker PCBs: A thicker PCB offers better support for LED beads and components, which is especially important in high-power applications where more LEDs are mounted, or where mechanical stability is essential.

3. Copper Thickness:

Copper thickness impacts the board’s ability to handle electrical current and heat dissipation:

- Current Handling: The copper thickness should be adjusted based on the current requirements of the LED system. For higher current applications, thicker copper is needed to safely carry the current without overheating.

- Copper Thickness Range: The standard copper thickness for LED PCBs is between 18µm and 105µm. Higher currents require thicker copper to ensure proper electrical performance and prevent overheating.

4. Solder Mask Color:

The solder mask color can have functional and aesthetic implications, especially for LED lighting products:

- White Solder Mask: Widely used in LED PCBs due to its reflective properties, which help maximize light output. There are different types of white solder masks, including:

- Super White: Known for its high reflectivity, ideal for maximizing light output.

- Blue-White: Offers a slightly cooler tint, often used in certain types of lighting applications.

- Milky White: Has a softer, warmer appearance, which may be desirable in decorative or ambient lighting.

- Matte Black and Green: Black or green solder masks are typically used in applications where aesthetics or light reflectivity are less of a concern. Matte black can also reduce light reflection, which may be useful in specific lighting designs or display technologies.