Semiconductor Chip Analysis & Failure Analysis: Engineering Evaluation for Electron Devices

Focus Keyphrase: Semiconductor Chip Analysis

Secondary Keywords: Failure Analysis, Electron Devices and Circuits, Microcontroller, Optical Inspection, Integrated Circuit.

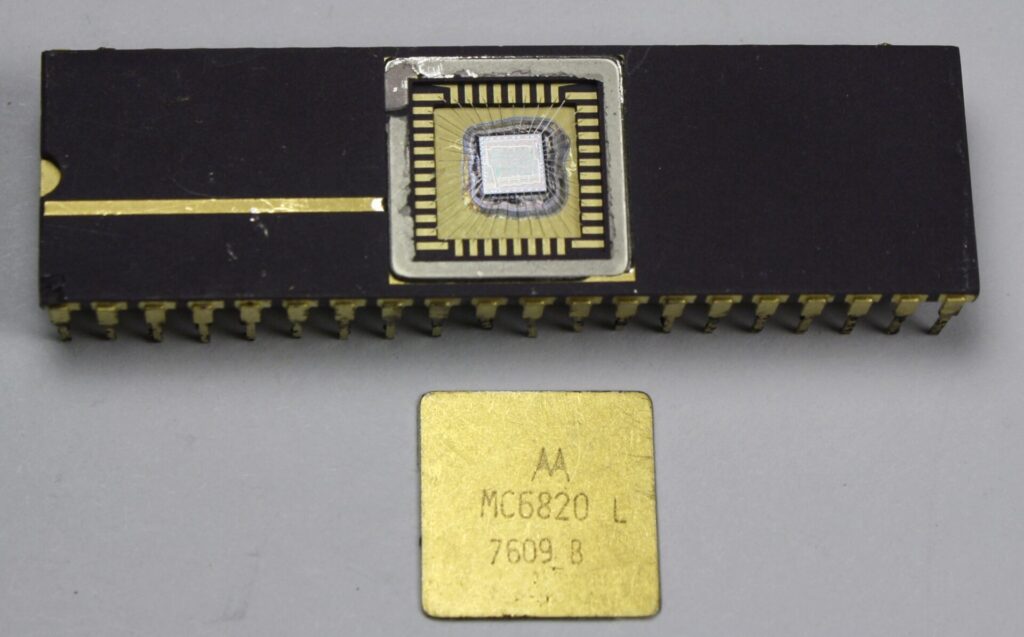

Semiconductor Chip Analysis is the “forensic science” of the electronics industry. Whether verifying the authenticity of a supply chain batch or diagnosing a field failure, understanding the internal structure of Integrated Circuits (ICs) is critical.

At CtrlcPCB, we provide professional engineering evaluation services. We go beyond simple visual checks, utilizing advanced Optical Inspection and electrical testing to analyze complex Electron Devices and Circuits for failure analysis, reliability studies, and documentation recovery.

When is Chip Analysis Required?

In the lifecycle of Electronic Components, engineers often face “black box” problems where the datasheet is insufficient. Chip analysis provides the missing data.

Common Engineering Scenarios:

-

Failure Analysis (FA): Determining why a Microcontroller or power IC failed in the field (EOS/ESD analysis).

-

Counterfeit Detection: Verifying if a batch of chips are genuine original parts or re-marked fakes.

-

Obsolete Component Evaluation: Analyzing legacy Electron Devices to find a modern functional equivalent.

-

Process Identification: Understanding the fabrication node and packaging technology of a competitor’s device.

Our Engineering-Oriented Analysis Approach

We treat chip analysis as a strict engineering discipline. Our lab focuses on non-destructive and minimally invasive techniques to preserve the integrity of your Electron Devices and Circuits.

1. Non-Destructive Optical Inspection

Before any physical action, we perform high-resolution Optical Inspection. This reveals external package defects, lead frame corrosion, and marking anomalies without opening the chip.

2. X-Ray & Internal Imaging

We use high-power X-rays to see through the epoxy package. This allows us to inspect wire bonds (gold/copper wires) and die attachment inside the Integrated Circuit without decapsulation.

3. Decapsulation & Die-Level Inspection

For deeper analysis, we use chemical or laser decapsulation to expose the silicon die. This allows for:

-

Die Marking Verification: Confirming the chip is truly the Microcontroller part number it claims to be.

-

Layout Observation: Studying the floorplan of the IC Board Design (at the silicon level) to understand functional blocks.

Compliance & Responsible Engineering

We operate a compliance-first lab. Semiconductor Chip Analysis is a powerful tool, and we ensure it is used for legitimate engineering purposes.

-

Authorization: Customers must confirm legal ownership or valid authorization for the Electronic Components submitted.

-

Purpose Limitations: Analysis is strictly for Failure Analysis, maintenance, quality control, or academic research.

-

Security Policy: We do not engage in firmware extraction, encryption bypass, or any activity that compromises device security.

Why Choose CtrlcPCB for Device Evaluation?

Analyzing Electron Devices and Circuits requires more than just a microscope; it requires experienced engineers who understand semiconductor physics.

-

Engineering-Driven: We interpret the data, not just take pictures.

-

Comprehensive Reporting: You receive a detailed technical report with high-res die photography and X-ray images.

-

Confidentiality: All samples and data are handled under strict NDA protocols.

🚀 Start Your Chip Evaluation Project

Do you have a failed Microcontroller or an unknown IC that needs identification? Let our engineering team provide the insights you need.

Ready to Analyze?

-

Define Scope: Tell us if you need Failure Analysis or structural evaluation.

-

Submit Samples: Send your Electronic Components for a secure assessment.