Rigid-Flex PCB Manufacturer

HUANG TE PCB provides Rigid-Flex PCB Manufacturing and Assembly with Fast Delivery and Competitive Prices.

services

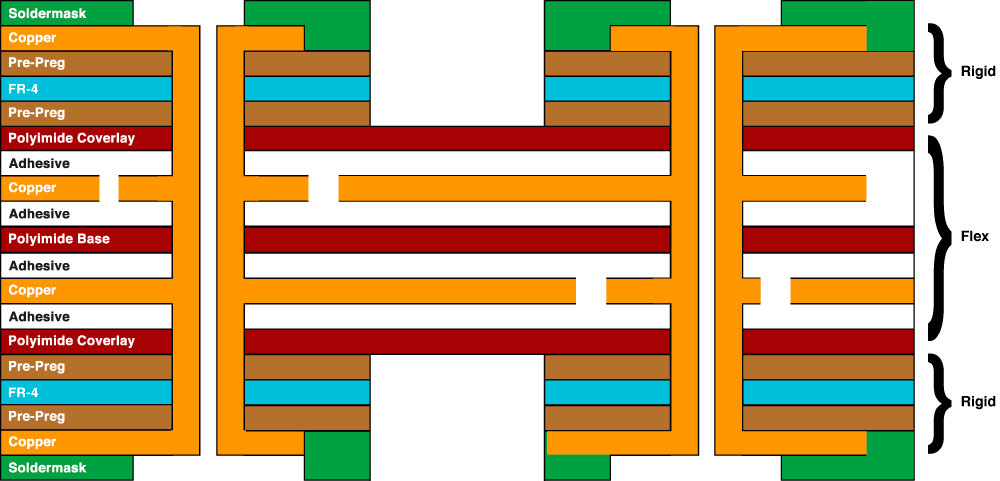

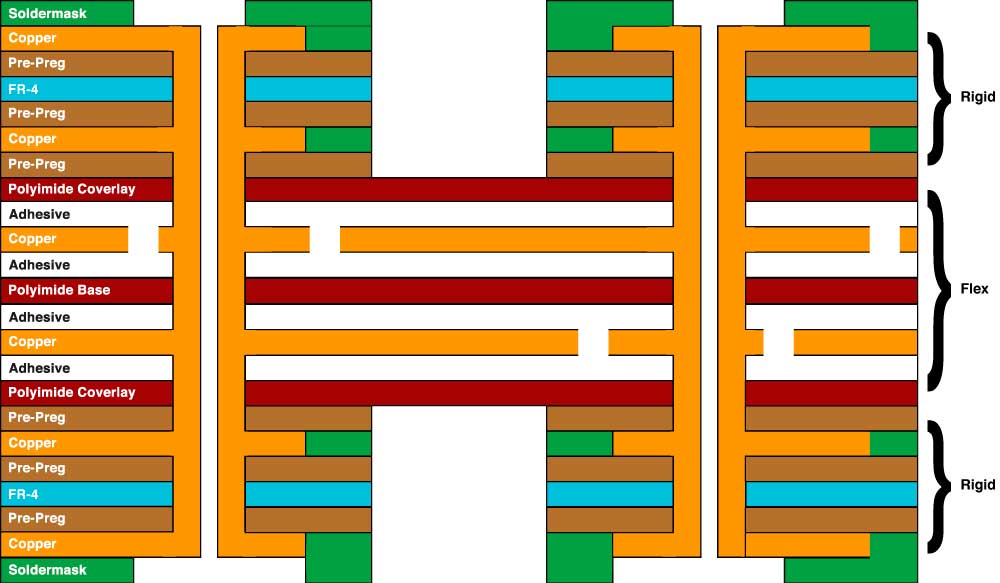

Rigid-Flex PCB Stackup

See the left 4 Layers and 6 Layers Rigid-Flex PCB Stackup, you can clearly see the difference from Rigid PCB and Flexible PCB. Meanwhile you can click to see the Flexible PCB Stackup.

If you have any questions about Rigid-Flex Stackup, or design, manufacturing questions, don’t to contact for help.

What people say

Rigid-Flex PCB is made of two parts, which is flexible PCB and Rigid PCB. so the material includes flexible PCB material and Rigid PCB material. The common Rigid PCB board material is FR4, but for hybrid Rigid-Flex PCb, the rigid PCB also can be metal core PCB, rf PCB, and other PCB material. The following just list FR4 as Rigid PCB board material.

| Material for rigid PCBs | Tg | CTE-z (T<Tg) | εr, Dk- Permittivity | Dk Loss Tangent | Electric Strength | Surface Resistivity | Tracking resistance CTI | Td value | Peel strength |

|---|---|---|---|---|---|---|---|---|---|

| °C | ppm/°C | @1GHz | @1GHz | KV/mm | MO | PLC | °C | N/mm | |

| ISOLA Duraver DE104 Standard FR4 | 135° | 70 | 4,4 | 0,020 | 54 | 1,0 x 10^6 | 2 | 315° | 1,6 |

| Shengyi S1141 FR4 alternative | 140° | 65 | 4,6* | 0,015* | 60 | 5,4 x 10^7 | 3 | 310° | 1,8 |

| ISOLA Duraver DE104 KF FR4 tracking resistant | 135° | 45 | 4,6 – 4,9 | 0,020* | 39 | 1,0 x 10^6 | 1 | 315° | 1,6 |

| ISOLA DE156 FR4 halogen-free | 155° | 45 | 4,0 | 0,016 | 36 | 4,0 x 10^6 | – | 390° | 1,4 |

| ISOLA IS400 FR4 MidTg | 150° | 50 | 4,0** | 0,020 | 48 | 3,0 x 10^6 | 3 | 330° | 1,4 |

| ITEQ IT-158 FR4 MidTg alternative | 155° | 60 | 4,3 | 0,016 | 60 | 1,0 x 10^10 | – | 345° | 1,7 |

| ITEQ IT-180A FR4 HTg | 175° | 45 | 4,4 | 0,015 | 45 | 3,0 x 10^10 | – | 345° | 1,4 |

| Shengyi S1000-2 FR4 HTg alternative | 180° | 45 | 4,8* | 0,013* | 63 | 7,9 x 10^7 | 3 | 345° | 1,4 |

| ISOLA IS410 FR4 HTg, CAF-Enhanced | 180° | 55 | 4,0 | 0,019 | 44 | 8,0 x 10^6 | 3 | 350° | 1,2 |

| ISOLA IS420 FR4 HTg, CAF-Enhanced alt. | 170° | 45 | 4,0 | 0,016 | 54 | 3,0 x 10^6 | 3 | 350° | 1,3 |

| Material for flexible PCBs | Recommended max. operating temperature | Copper type | Tg | Ԑr, Dk- Permittivity | CTE-z (T<Tg) | Electric Strength | Surface resistivity | Peel strength |

|---|---|---|---|---|---|---|---|---|

| °C | * | °C | @1MHz | ppm/°C | KV/mm | MΩ | N/mm | |

| Polyimide + Adhesive | ||||||||

| Shengyi SF305 | 105° | Rolled Copper | – | 3,6 | 21 | – | 1 x 10^5 | 1,1 |

| Polyimide | ||||||||

| DuPont Pyralux AP | 180° | Rolled Copper | 220 | 3,4 | 25 | 256 | 1 x 10^10 | 1.8 |

| Panasonic RF775 | 130° | Electrolytically Deposited Coppe | 343 | 3,2 | – | 276 | 1 x 10^8 | 1,7 |

| Thinflex W-05050 | 105° | Electrolytically Deposited Coppe | 350 | 3,3 | 24 | 216 | 1 x 10^5 | 0.6 |

| PI Coverlay | ||||||||

| 105° | – | – | – | – | – | 3 x 10^6 | – | |

| DuPont Pyralux FR | 180° | – | – | 3.5 | – | 138 | 1 x 10^7 | – |

| Adhesive tape | ||||||||

| 3M 9077 | 150° | – | – | – | – | – | – | – |

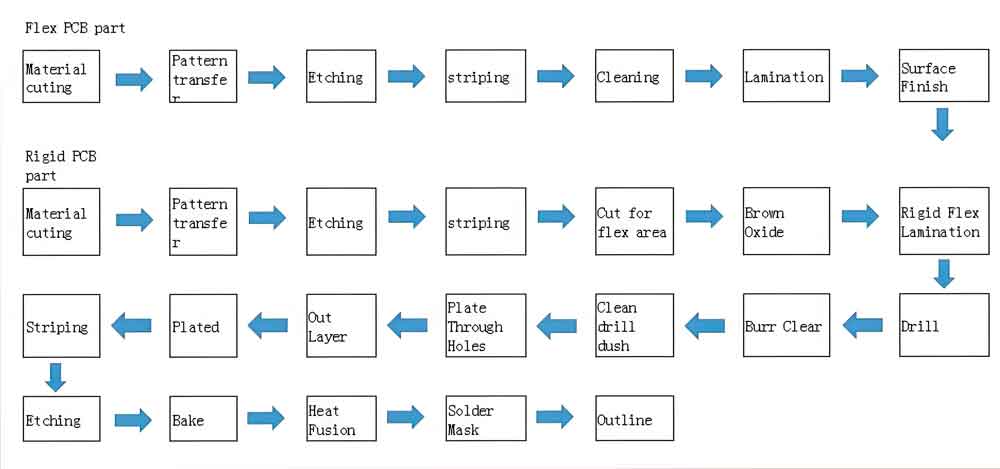

Typical Rigid-Flex PCB Manufacturing Flow Chart

Rigid-Flex PCB Manufacturing Capability

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 2 – 30layers |

| Order Quantity | 1pc – 10000+pcs |

| Build Time | 2days – 5weeks |

| Material | Polyimide, High Tg polyimide, FR4, High Tg FR4 |

| Material Brand | Shengyi, Ventec, ITEQ, Rogers, Panasonic, Dupont, Taiflex |

| Board Size | Min 6mm x 6mm Max 500mm x 1,000mm |

| Board Thickness | 0.08mm – 5.0mm |

| Copper Weight (Finished) | 0.5oz – 4.0oz |

| Min Tracing/Spacing | 0.04mm/0.04mm |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL – Hot air solder leveling Lead – free HASL – RoHS ENIG – RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | Laser Drilled: 3mil, Mechanical Drilled: 4 mil; |

| Max Mechanical Through Hole Aspect Ratio | 14:1 |

| Min Single-ended Impedance Tolerance Min Differential Impedance Tolerance | ±8% |

| Min Soldermask Bridge | 0.07 mm |

| Min BGA Pitch | 0.45 mm |

| Other Techniques | HDI Gold fingers Stiffener |

Get In touch

We have companies or branches all over the world, providing services without distance and caring without time difference.

Address:

20A, West Building, Shanghai Science and Technology Capital

Call Us:

+86 18221220431

Email: