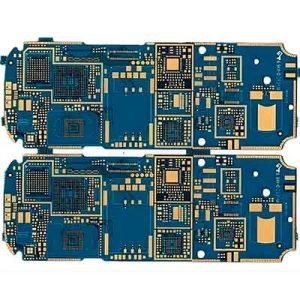

One-Stop PCB Solutions: From PCB Design to Flexible PCB Fabrication

Focus Keyphrase: PCB Design

Secondary Keywords: Flexible PCB, PCB Layout, PCB Prototyping Services, IC Board Components.

Your Engineering Partner for Complex Electronics

True One-Stop Service isn’t just about manufacturing; it’s about Engineering.

At CtrlcPCB, we engage earlier than most factories. We start at the PCB Design stage, helping you optimize your PCB Layout for cost and performance before a single board is etched. Whether you are building a rigid industrial controller or a complex Flexible PCB for wearables, we provide the seamless link between concept and reality.

1. PCB Design & DFM Engineering

Most factories just verify files; we optimize them.

-

Advanced PCB Layout: Our team handles high-speed, RF, and mixed-signal designs. We don’t just route tracks; we engineer signal integrity.

-

Design for Manufacturing (DFM): We review your PCB Design to catch issues like acid traps or impedance mismatches early.

-

Stackup Planning: Critical for Flexible PCB and HDI boards, ensuring the right material blend (e.g., Polyimide + FR4) for durability.

2. Advanced Fabrication: Rigid & Flexible PCB

We are a source factory with capabilities that go beyond the basics.

-

Flexible PCB Expertise: We specialize in Flex and Rigid-Flex boards, supporting dynamic bend areas and coverlay constraints.

-

HDI Technology: Laser microvias, via-in-pad, and sequential lamination for high-density PCB Design.

-

Material Options: From standard FR-4 to high-frequency Rogers and aluminum-based cores for thermal management.

3. PCB Prototyping Services & Assembly

Speed is critical for R&D. Our PCB Prototyping Services are designed for agility.

-

Rapid Turnaround: Prototype boards in as fast as 24 hours.

-

Component Sourcing: We manage the entire supply chain for IC Board Components, ensuring authentic parts from authorized distributors.

-

Assembly: Whether it’s a simple prototype or a complex BGA population, our SMT lines handle it with precision.

4. Reverse Engineering (Legacy Support)

Lost your original files? We can recover your PCB Design data.

-

Scan & Rebuild: We generate new Gerber files and PCB Layout data from physical samples.

-

BOM Recovery: Identifying obsolete IC Board Components and suggesting modern replacements.

Quality Control & Engineering Documentation

We provide the documentation you need to validate your design.

-

Deliverables: DFM reports, Impedance control reports, and Stackup drawings.

-

Testing: Flying probe testing for every Flexible PCB to ensure trace continuity after bending.

Typical Lead Time

-

PCB Prototyping Services: 3–7 days (Standard Rigid), 5-10 days (Flexible/HDI).

-

Assembly: 7–15 days (Turnkey with component sourcing).

How to Get a Quote

To leverage our engineering support, please provide:

-

Gerber Files: Or your PCB Design source files for layout review.

-

BOM List: For sourcing IC Board Components.

-

Special Requirements: Specify if you need Flexible PCB stiffeners or impedance control.

Start with Design, Finish with Product.

Partner with CtrlcPCB for a truly integrated engineering experience.