PCB Manufacturing

HUANG TE PCB provide PCB Prototype Services and product-run services to help you get your product to market better.

The Type of PCB we make

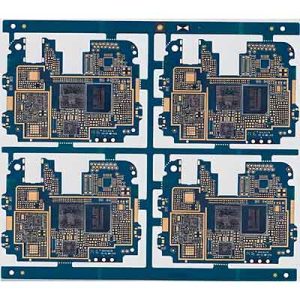

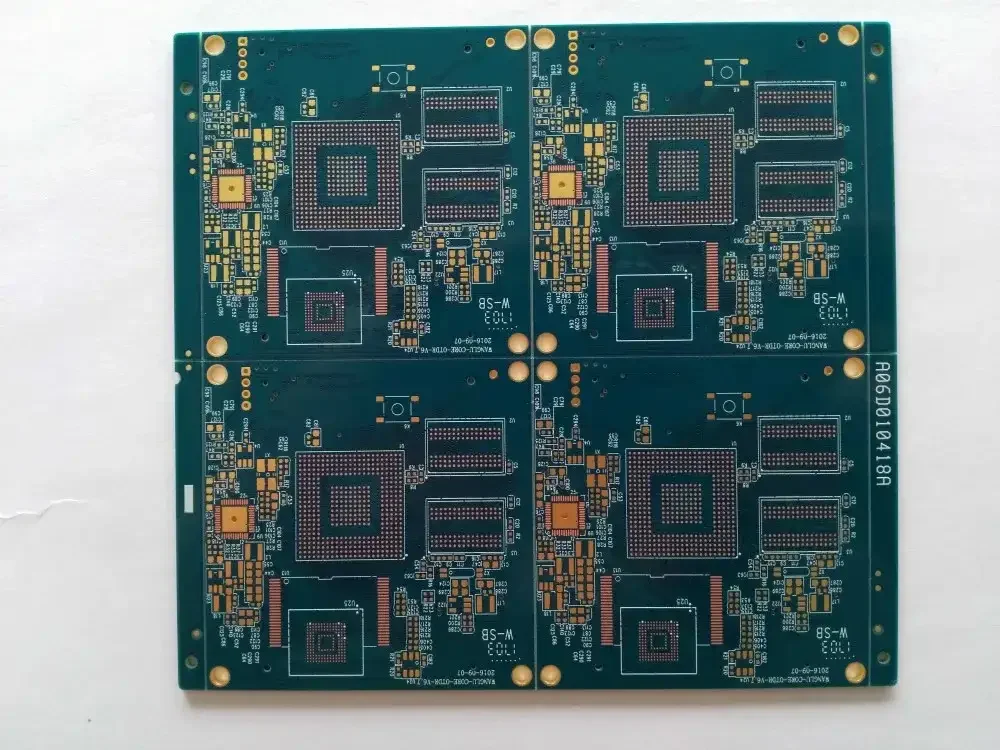

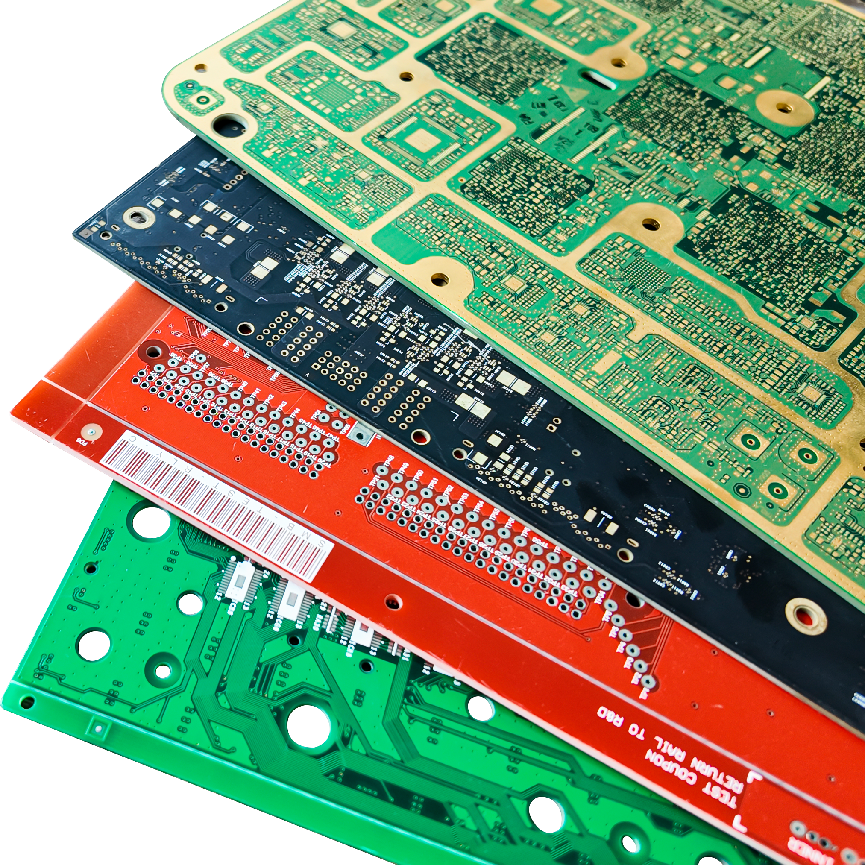

Rigid PCB

HUANG TE provides Rigid PCB manufacturing Services, such as CEM, FR4 PCB, and other rigid materials.

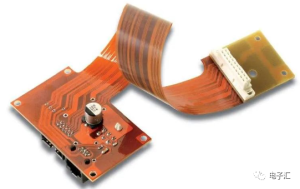

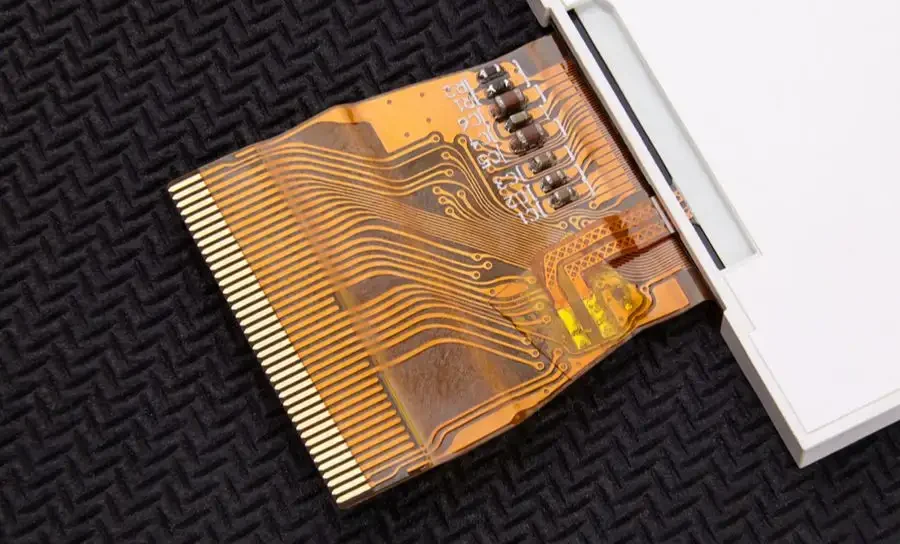

Flexible PCB

Flexible PCBs are lightweight, durable, and adaptable to complex shapes, ideal for compact electronic devices and wearable technology.

Rigid-Flex PCB

Rigid-Flex PCBs combine the benefits of both rigid and flexible circuits, offering strength and flexibility for space-constrained, high-performance applications.

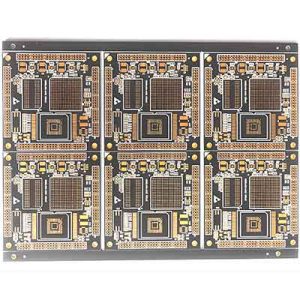

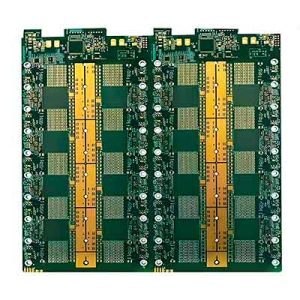

HDI PCB

HDI PCBs feature high-density interconnections for compact, high-performance electronics, offering more functionality in smaller, lighter designs.

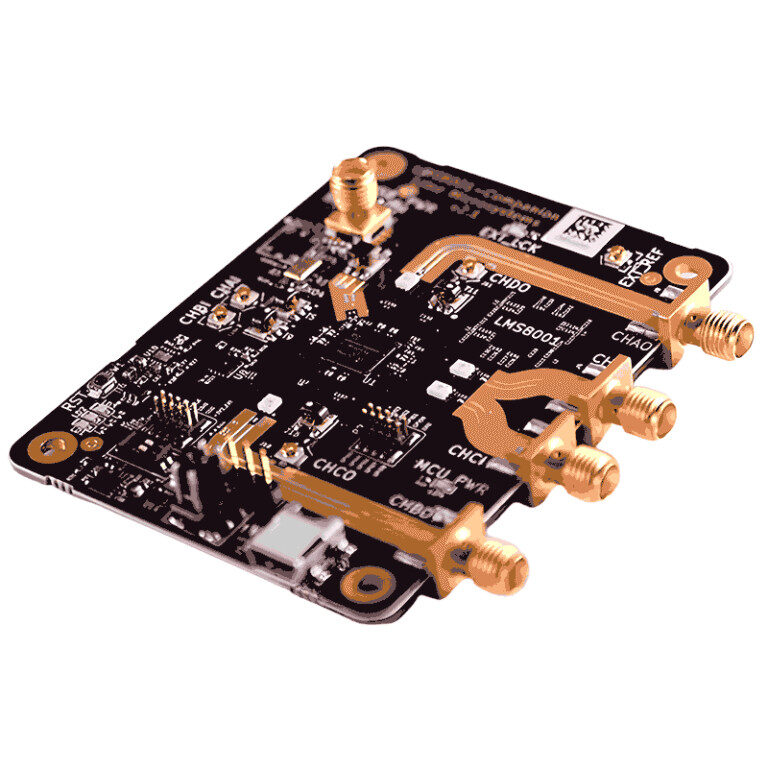

RF PCB

RF PCBs are designed for high-frequency signal transmission, ensuring stable performance in communication devices, radar, and wireless applications.

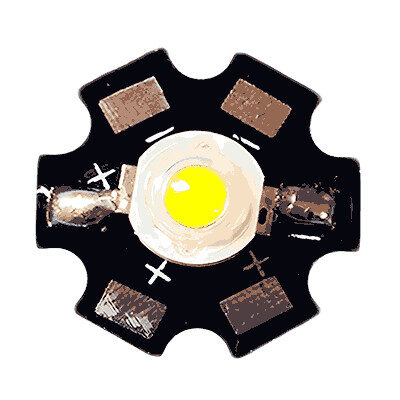

Metal Core PCB

Metal Core PCBs offer superior heat dissipation, which is ideal for high-power applications like LED lighting and automotive electronics.

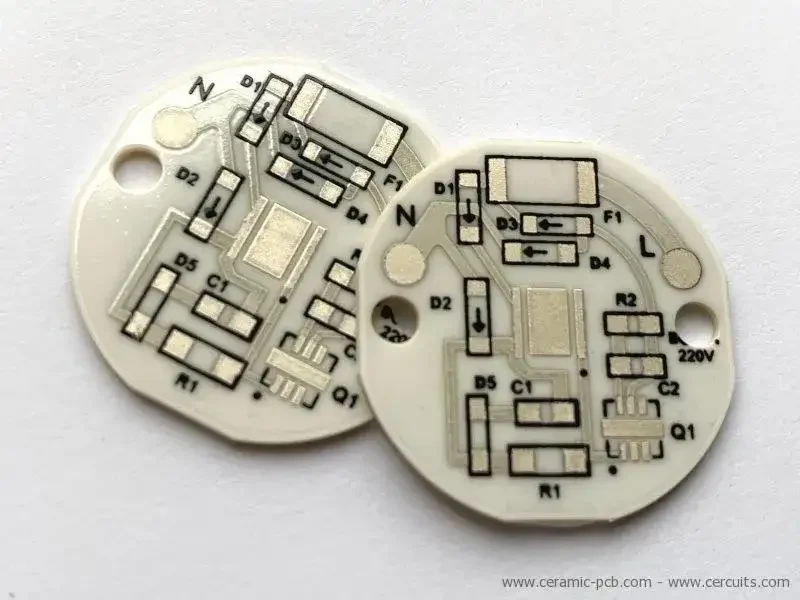

Ceramic PCB

Ceramic PCBs provide excellent thermal conductivity and electrical performance, perfect for high-power and high-frequency applications.

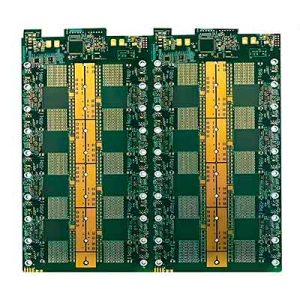

Heavy Copper PCB

Heavy Copper PCBs(>= 3 oz copper) are designed for high-current applications, offering enhanced power handling and durability for demanding electronic systems.

High Tg PCB

High Tg PCBs are built for high-temperature environments, offering improved thermal stability and reliability in demanding electronic applications.

Our Numbers of PCB Manufacturing

services

Industries We Server

Automotive and Electric vehicl

Medical

Aviation

IOT

Industry Control

Data Center and Server

Consumer Electronics

Lighting

Marine

Military Industrial

Our Numbers of PCB Manufacturing

Our PCB Manufacturing Capability

| Feature | Capability |

| PCB Type | Rigid PCB(CEM, FR4), Flexible PCB, Rigid-Flex PCB, MCPCB(Aluminum PCB), Ceramic PCB, RF PCB, etc. |

| Number of Layers | 1 – 32layers |

| Order Quantity | 1pc – 10,000,000 pcs |

| Build Time | 2days – 5weeks (Expedited Service) |

| Material | FR-4 Standard Tg 150°C, FR4-High Tg 170°C, FR4-High-Tg 180°C, FR4-Halogen-free, FR4-Halogen-free & High-Tg |

| Board Size | Min 6*6mm | Max 600*700mm |

| Board size tolerance | ±0.1mm – ±0.3mm |

| Board Thickness | 0.4mm – 3.2mm |

| Board Thickness Tolerance | ±0.1mm – ±10% |

| Copper Weight | 0.5oz – 6.0oz |

| Inner Layer Copper Weight | 0.5oz – 2.0oz |

| Copper Thickness Tolerance | +0μm +20μm |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Blue, Black, Red, Yellow |

| Surface Finish | HASL – Hot Air Solder Leveling Lead Free HASL – RoHS ENIG – Electroless Nickle/Immersion Gold – RoHS ENEPIG – Electroless Nickel Electroless Palladium Immersion Gold – RoHS Immersion Silver – RoHS Immersion Tin – RoHS OSP -Organic Solderability Preservatives – RoHS |

| Min Annular Ring | 3mil |

| Min Drilling Hole Diameter | 6mil, 4mil-laser drill |

| Min Width of Cutout (NPTH) | 0.8mm |

| NPTH Hole Size Tolerance | ±.002″ (±0.05mm) |

| Min Width of Slot Hole (PTH) | 0.6mm |

| PTH Hole Size Tolerance | ±.003″ (±0.08mm) – ±.006″ (±0.15mm) |

| Surface/Hole Plating Thickness | 20μm – 30μm |

| SM Tolerance (LPI) | .003″ (0.075mm) |

| Aspect Ratio | 1.10 (hole size: board thickness) |

| Test | 10V – 250V, flying probe or testing fixture |

| Impedance tolerance | ±5% – ±10% |

| SMD Pitch | 0.2mm(8mil) |

| BGA Pitch | 0.2mm(8mil) |

| Chamfer of Gold Fingers | 20, 30, 45, 60 |

| Other Techniques | Gold fingers Blind and Buried Holes peelable solder mask Edge plating Carbon Mask Kapton tape Countersink/counterbore hole Half-cut/Castellated hole Press fit hole Via tented/covered with resin Via plugged/filled with resin Via in pad Electrical Test |

Our Numbers of PCB Manufacturing