PCB Layout Design Services

services

Our PCB Layout Services Content

We offer a wide range of services, including:

- Schematic Capture: We convert your circuit ideas into a detailed schematic diagram.

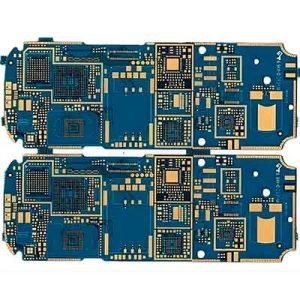

- PCB Layout Design: We design the physical layout of the PCB, optimizing for performance, reliability, and manufacturability.

- Design for Manufacturing (DFM): We ensure that your design is ready for efficient and cost-effective production.

- Fabrication Files: We generate manufacturing files for you, like Gerber files.

- Prototype Testing: We can assist with prototype testing to verify the functionality and performance of the design.

- Production Run: We also provide PCB Manufacturing and Assembly Services for your production run.

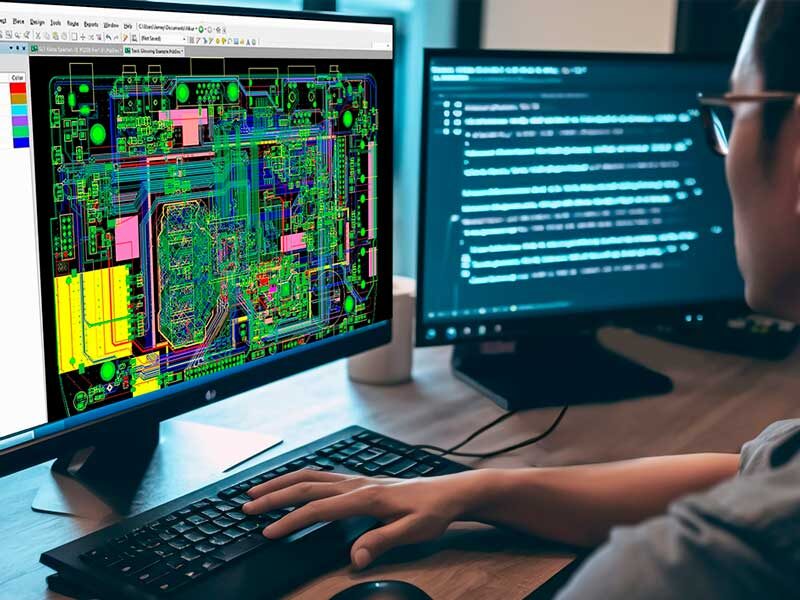

PCB Layout Software we use

Altium Designer

Allegro

OrCad

PCB Layout Services Process

The creation of a PCB layout is a detailed procedure that involves converting a schematic into a physical blueprint, deciding the location of each component on the board, and establishing the interconnections among them. Here are the primary stages involved in formulating a PCB layout:

Schematic Design: The journey begins with the creation of a detailed schematic diagram of your circuit.

Component Placement: The subsequent stage involves determining the location of each component on the board.

Routing: This stage involves the creation of paths (traces) that electrically interconnect the components.

Design Rule Check (DRC): This is a process automated by software that checks if the layout adheres to the rules set by the PCB fabrication house.

Gerber Generation: The final stage involves the generation of Gerber files, which are the standard file format for manufacturing PCBs.

In addition to these stages, there are several factors to consider during the PCB layout process:

Component Placement Optimization: Components should be strategically placed to minimize trace lengths and prevent crossing signal paths.

Signal Traces and Routing: Special care should be taken to avoid signal integrity issues such as crosstalk and electromagnetic interference.

Thermal Considerations: The layout should consider heat dissipation, especially for high-power components.

Ground Plane Design: A well-designed ground plane can help reduce noise and improve signal integrity.

Design Rule Checks (DRCs): Regular DRCs should be conducted throughout the design process to identify and correct errors early.

Manufacturer Collaboration: Close collaboration with the PCB manufacturer can help ensure the design is optimized for manufacturability.

Remember, the design of a PCB layout requires careful planning, meticulous attention to detail, and compliance with industry standards and guidelines. I hope this provides a comprehensive overview of the PCB layout process. If you have any more questions, don’t hesitate to ask!

PCB Layout Services Process

Expertise

Our team has extensive experience in PCB design across various industries and applications.

Quality

We adhere to strict quality standards to ensure the reliability and longevity of your products

Efficiency

We use advanced design tools and techniques to optimize the design process and reduce time-to-market.

Support

We provide ongoing support throughout the design process, from initial concept to final production.

PCB Layout Services Process

Recovering Legacy PCBs | Industrial PCB Production & Cloning

PCBs & Industrial PCB Production: Reviving End-of-Life Electronics Focus Keyphrase: PCBs Secondary Keywords: PCB Board,

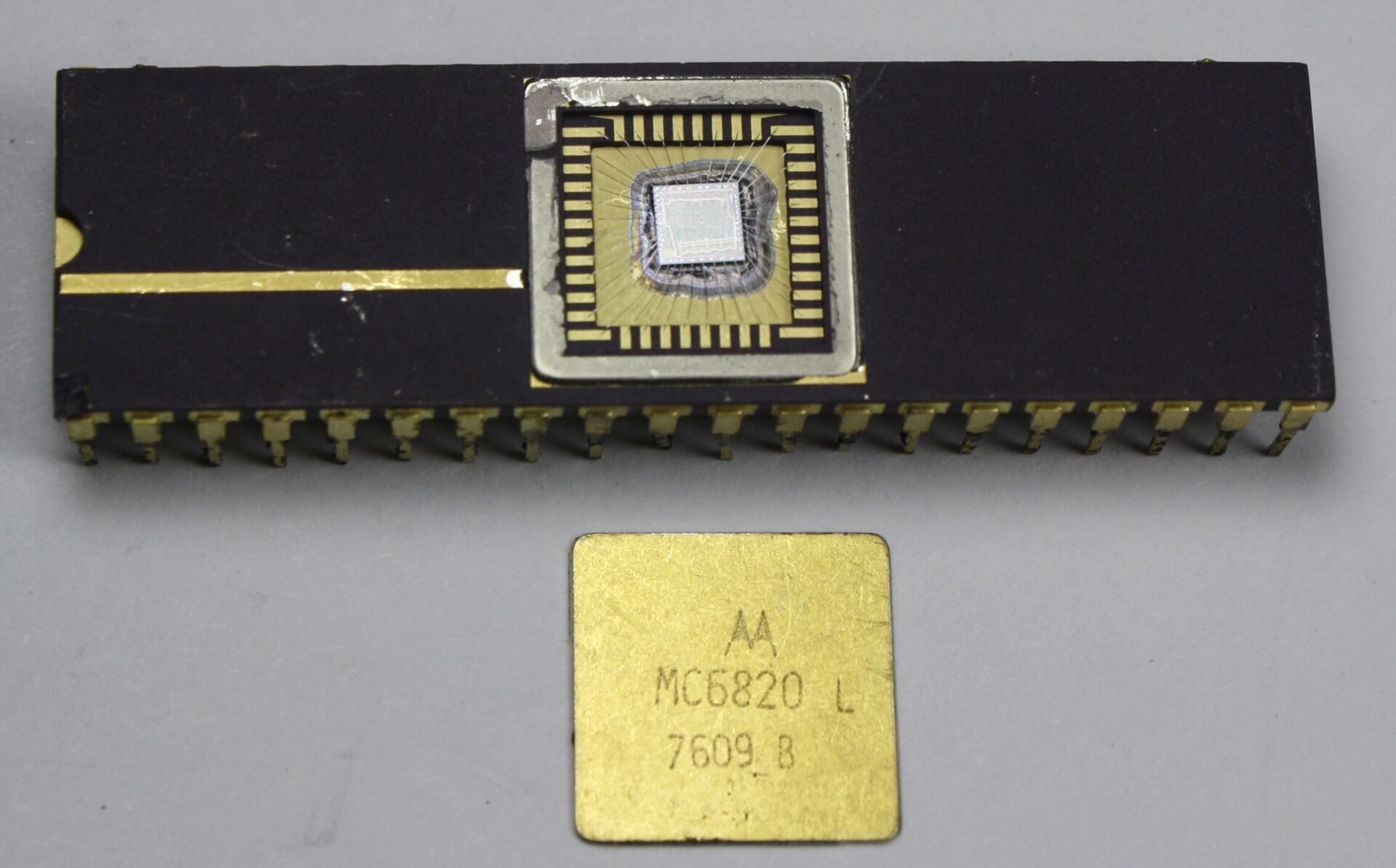

Locked or Obsolete Chips? We Deliver Practical Decryption Solutions for Your Project

Chip Analysis & Component Verification: Protecting Electronic Devices Manufacturers Focus Keyphrase: Circuit Board Components Secondary

In-House SMT for PCB Board | Direct Printed Circuit Manufacturer

In-House SMT Lines for PCB Board Assembly: Competitive Pricing from a Source Factory Focus Keyphrase:

One-Stop PCB Solutions | PCB Design, Layout & Flexible PCB

One-Stop PCB Solutions: From PCB Design to Flexible PCB Fabrication Focus Keyphrase: PCB Design Secondary

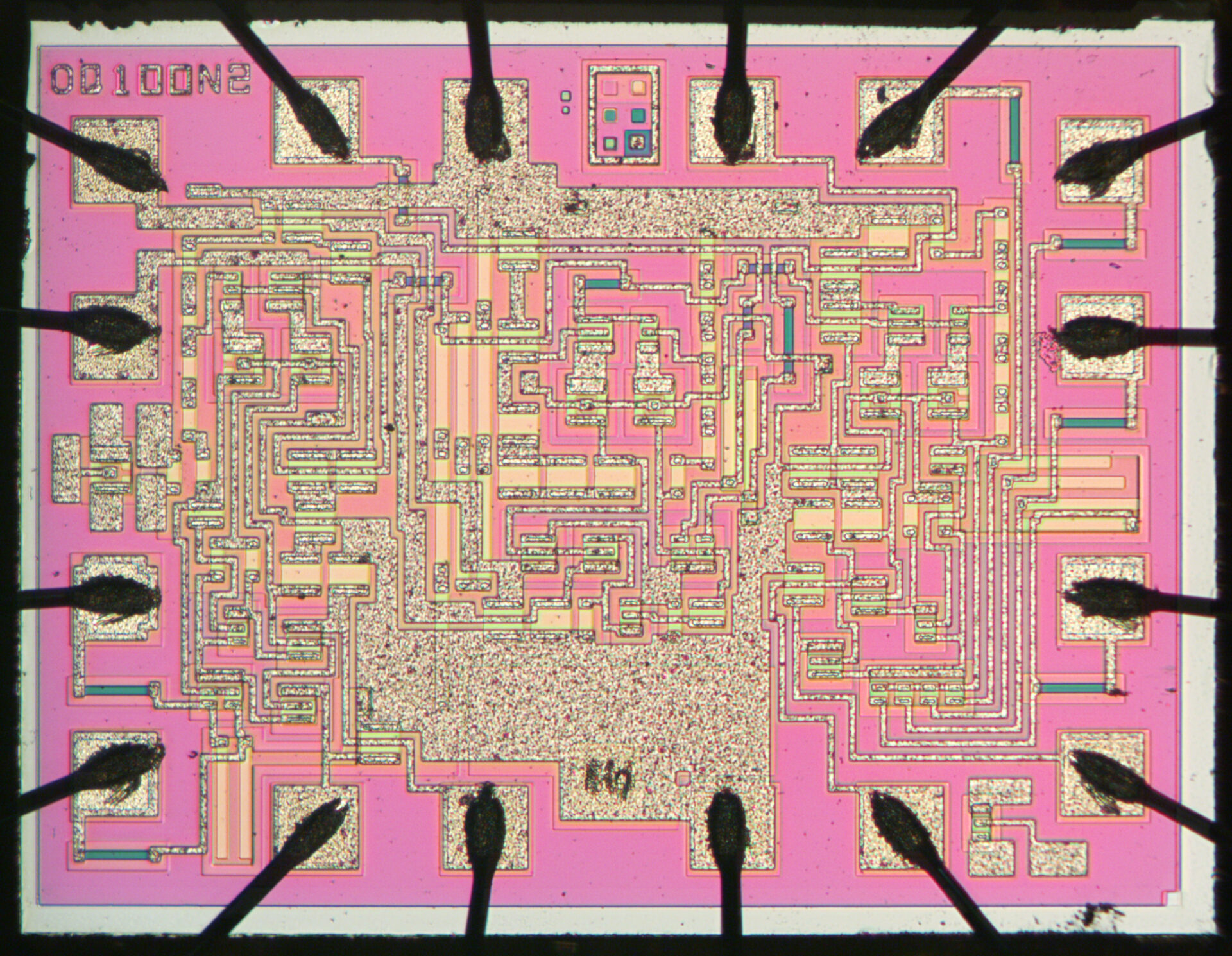

Semiconductor Chip Analysis & Security Evaluation | For Microcontrollers

Semiconductor Chip Analysis & Security Evaluation: Engineering Assessment for Microcontrollers Focus Keyphrase: Semiconductor Chip Analysis

SMT Soldering for Electron Devices | Industrial PCB Production

SMT Soldering: Bridging Electron Devices and Circuits for Industrial Production Focus Keyphrase: SMT Soldering Secondary

PCB Fabrication Process Explained (From Design to Finished Board)

PCB Fabrication Process Explained: From Schematic Design to Finished Board Focus Keyphrase: PCB Fabrication Process

Semiconductor Chip Analysis Services

Semiconductor Chip Analysis & Failure Analysis: Engineering Evaluation for Electron Devices Focus Keyphrase: Semiconductor Chip

PCB Reverse Engineering Services | Design Recovery & PCB Repair Analysis

PCB Reverse Engineering Services: Precision PCB Design Recovery & Analysis Focus Keyphrase: PCB Reverse Engineering