PCB Design Services

HUANG TE PCB is China’s company for top-quality PCB design services. We’ve been designing Printed Circuit Boards (PCBs) for over 20 years. We give you great service that fits exactly what you need for your electronics.

Our company has seasoned electronic designers who give full PCB design and layout services. If you are working on an electronic part and want to develop a design for your PCB, our team is here to help. We make sure everything is correct, quick, and works well from start to finish. We pay attention to signal integrity to make sure your PCBs work in harsh environment.

From the first step of schematic capture to the final manufacturing outputs, we give you new and reliable plans that help your product to perform seamless.

services

Electronic Design Services

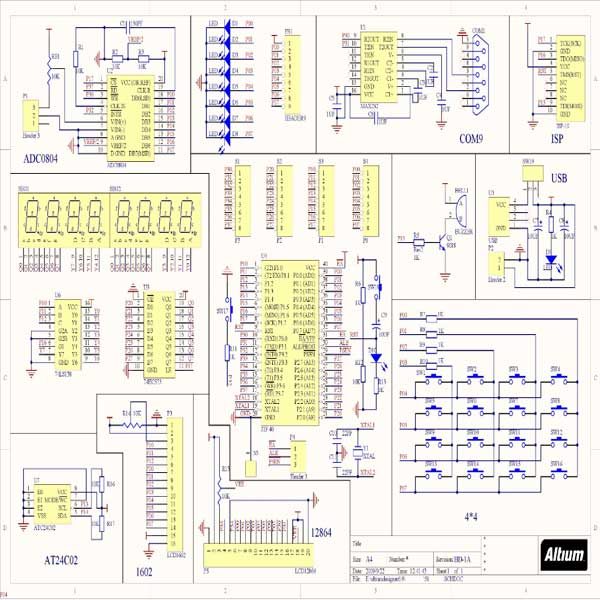

Our schematic capture service is the starting point for strong PCB designs. We draw clear and correct schematic diagrams. These diagrams are like the plan for your electronic circuits. We are very careful when we do this. This helps everyone understand the design, stops mistakes, and makes it easy to work together on your PCB project.

What You Get:

- Circuit plans that are correct and have no errors

- Easy-to-understand and complete papers about the design

- Better teamwork and talking about the project

- A good start for making your PCB layout

services

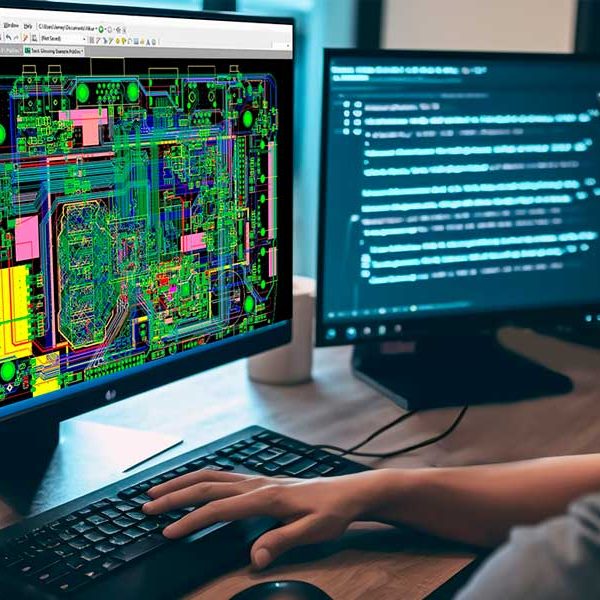

PCB Layout Design Services

Our PCB layout design service means you can get best plan for your circuit board. We design it to work really well and do everything you need. Our designer team is IPC and CID certified. They carefully place all the parts and plan the PCB routing. This makes sure the signal integrity is good, meaning the electricity flows cleanly. We also work to stop EMC/EMI problems, which are like electrical noise that can cause trouble. We put significant focus on Design for Manufacturability. We want to give you PCBs that are dependable, small, and don’t cost too much to build.

What You Get:

- Designs that work great and send signals clearly

- Parts put in the best places with good wiring

- Less electrical noise (EMI)

- PCBs that are easier to build and cheaper

services

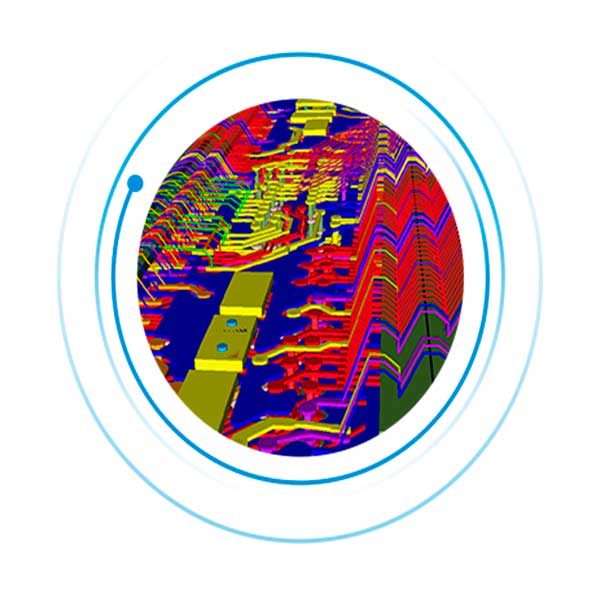

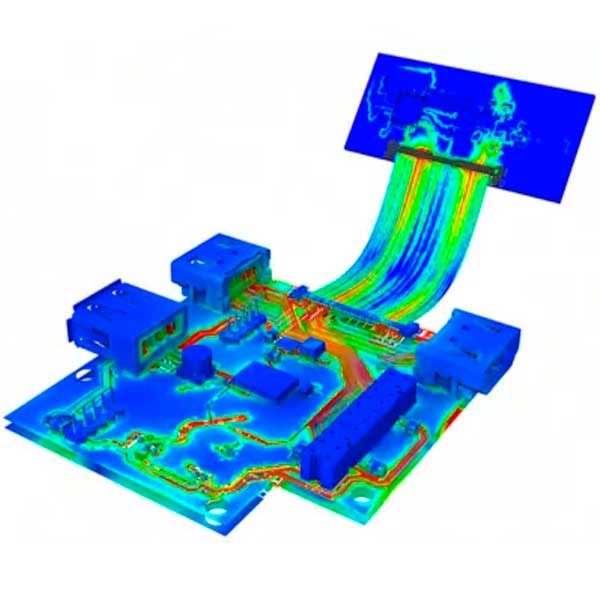

Simulation and Testing

Our Simulation and Testing services are very important. We use them to check your PCB design before we actually build it. We use special computer programs to test how the design will work. This is like trying it out in the computer first. We look for problems like signal reflections (like echoes in electricity) or thermal hotspots (parts that get too hot). We make sure your design works right, is dependable, and follows the rules everyone in the industry uses. Doing this early helps us fix problems before they cost you time and money. It’s a proactive approach that saves time and resources.

What You Get:

- Find design problems early

- Make sure your design works and is dependable

- Know that your design meets the rules

- Less chance of mistakes and having to redo work later

services

EMC/EMI Analysis

Our special EMC/EMI Analysis service is very important. We look for and fix things that can cause electromagnetic interference. EMI is like electrical noise that can mess up how your product works. We also check if your design follows the rules for electromagnetic compatibility. Following these rules means your product won’t make too much noise and won’t be bothered by noise from other devices.

What You Get:

- Less electrical noise (EMI) problems

- Designs that follow EMC rules

- Clearer signals and better signal quality

- Products that work better and are more dependable

services

Thermal Analysis

Thermal Analysis is very important when we design PCBs, especially for high-power and high-density applications. Our service checks how heat moves around in your PCB design heat dissipation. We make sure that thermal management is good so there is no component failure.

What You Get:

- We check how heat moves and spreads out in your design.

- We stop parts from getting too hot and getting damaged.

- Parts that last longer and are more dependable.

- Products that work better and stay reliable.

services

Design Changes & Making Designs Better

Our Design Modification and Optimization Services(Re-Design Services) optimize your design. If you want to make your design work faster, cost less to build (manufacturing costs), or be easier to make, we can help. Our team of experts can make your designs better for improved performance. We work on design improvements with tangible results.

What You Get:

- Designs that work better and do more

- Lower costs to make your PCBs

- PCBs that are easier to put together

- Products that are better quality and work well

services

Design for Manufacturability (DFM)

Our DFM services are very important. They make sure your PCB designs are production-ready. We make your design easy and cheap to make. We do this through PCBA and stopping mistakes. This makes the whole process for mass production and smoother.

What You Get:

- Designs that are made to be built easily

- Lower costs and fewer mistakes when making them

- PCBs that are quicker to put together

- Products that are more dependable and get to market faster

services

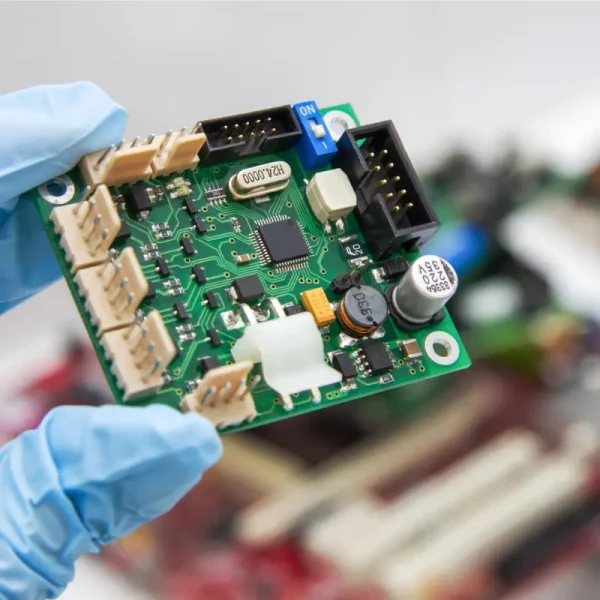

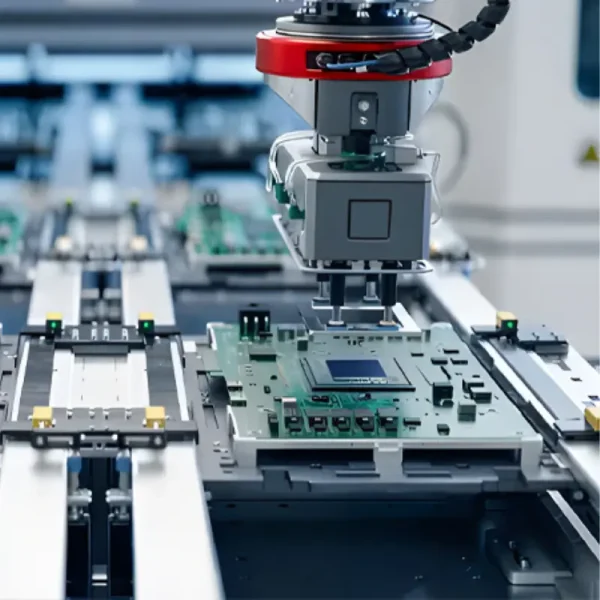

Product Making | PCB Assembly

What You Get:

- We handle all the steps to make your product

- From first samples to making lots of products

- PCBs that are made well and put together correctly

- Making products that are cheap and quick to build

PCB Design Software

PADS is another program we use. It is dependable and doesn’t cost too much. It has tools that can grow with your needs for designing, wiring, and making PCBs. PADS is a good choice if you need designs that are precise but not too complicated. It gives you cost-effective PCB design solution. It gives designer scalable tools.

Typical PCB Design Process

Finding Out What You Need

First, we talk to you to find out what you need. We want to know all about your project. We ask about what you want to build, how it needs to work, and any problems we might face. This first step is very important. It gives us a clear plan to design your PCB.

Drawing the Circuit Plan

Next, we draw a plan for schematic design. We take what you need and turn it into drawings that show all the parts and how they connect. Our designers draw these circuit plans very carefully to make sure they are correct and easy to understand.

Planning the PCB Layout

Then, we plan PCB layout. Our expert designers decide routing strategies. We want to make sure the signals travel cleanly, the board is easy to make, and it works well. We follow the industry best practices to make sure you get a high-quality and reliable PCB layout.

Testing on the Computer

After the layout, we do simulation and validation. Comprehensive simulations are run to check if the design works right and find any problems early. This rigorous testing makes sure everything works as it should, is dependable, and follows all the rules. This also saves time and resources because we find problems early.

Making a Sample PCB

Then, we go to prototype PCB manufacturing. This is a real PCB that we can touch and test. Making a high-quality PCB prototype lets us validate performance. We can find any problems we didn't see in the computer and fix them before making many PCBs.

Testing and Making it Better

After we have the sample PCB, we do rigorous testing). We check how it works and look for ways to make it better. Our designers might find things to improve and then change the design to make it work even better. We believe in iterative process until the final product is great and exceeds all requirements.

Output Documents From Our PCB Design Services

Gerber Files: These are special computer files that factories use to make your PCB. They tell the machines how to print each layer of the board.

Bill of Materials (BOM): This is a list of all the parts you need to build your PCB. It tells you what each part is and where to get it.

Schematic Diagram: This is a drawing that shows how all the electronic parts connect together in your circuit. It’s like a map of your circuit.

PCB Layout Files: These files show how the parts and wires are placed on the PCB. “Stack-up” tells you how the different layers of the PCB are put together.

Assembly Drawing: This is a picture that shows how to put all the parts onto the PCB. It’s like instructions for building your PCB.

Pick and Place files: These are files that tell the machines where to put each tiny part on the PCB when building it automatically. This is for fast, machine-made PCBs.

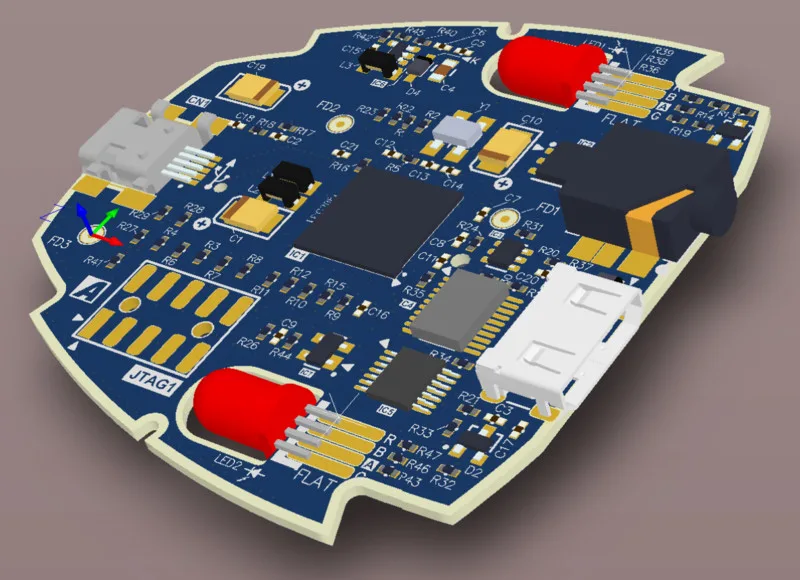

3D Model PDF: This is like a 3D picture of your PCB. It helps you see what the finished board will look like from all sides.

Netlist: This is a file that lists all the connections in your circuit. It’s used to make sure everything is wired up correctly when building and testing.

Drill Files: These files tell the machines where to drill holes in your PCB for putting in parts and connecting things.

Output Documents From Our PCB Design Services

Smartphones, tablet computers, e-book readers, smart watches, wireless headphones, game consoles, electronic dictionaries, MP3/MP4 players, VR devices, televisions, set-top boxes, digital cameras, electronic photo frames, home theater systems, electronic alarm clocks, wireless mice, wireless keyboards, Bluetooth speakers, electronic translators, electronic calculators, electronic cigarettes, electronic thermostats, electronic pet toys, electronic calendars, electronic pianos, electronic drums, smart headphone amplifiers, electronic reading lights, electronic music players, smart light bulbs, electronic bracelets, electronic pedometers, smart glasses, electronic fingerprint recognition devices, electronic locks, smart doorbells, electronic whiteboards, electronic display boards, electronic drawing boards, electronic lockers

PLC (Programmable Logic Controller), Industrial robot control board, Inverter, Servo drive, CNC machine tool control system, Industrial Ethernet switch, Sensor data acquisition module, Automated assembly line control system, Electronic measuring instrument, Smart factory MES system, Remote monitoring data acquisition system, Industrial pressure sensor, Industrial UPS power control board, Laser cutting machine control system, 3D printer main control board, Industrial robot power management module, High-voltage power grid detection equipment, Transformer monitoring system, Industrial temperature control system, Electronic weighing system, Production line equipment monitoring system, High-speed automatic sorting system, Automatic welding machine controller, Electronic stamping machine control module, Industrial water quality monitor, Remote intelligent inspection equipment, Industrial temperature sensor, Smart grid control system, Electronic gas meter, Electronic water meter, Wind turbine controller, Solar inverter, Lithium battery energy storage management system, Industrial vibration sensor, Remote intelligent inspection robot, High-power wireless charger, Electronic turbine control system, Elevator control system, High-voltage circuit protection system, Industrial Gas Detector