Battery management systems

- Complete BMS Solutions

- Tailored BMS Solutions

- Experienced BMS Engineering Team

- Advanced Facilities

- Specialized Electronic Manufacturing

About HUANG TE PCB

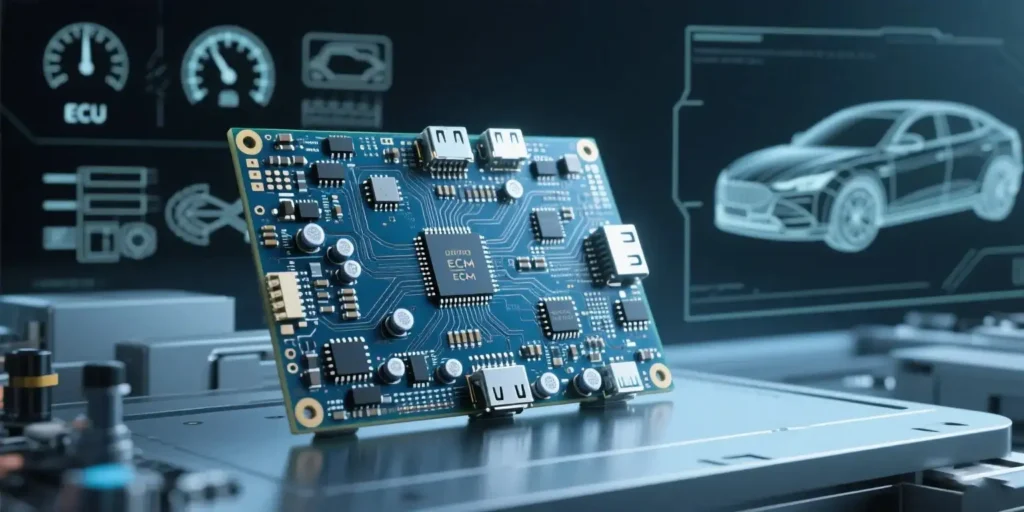

HUANG TE PCB is a leading expert in Battery Management Systems (BMS). As a top BMS solution provider, we recognize the pivotal role of BMS in contemporary battery technology. Industries such as electric vehicles, energy storage, and portable electronics significantly depend on BMS. HUANG TE PCB offers impeccable BMS services for modern applications. Our aim is to provide effective solutions with calm confidence, backed by our proven expertise. Such power supplies are low cost and simple to design onto a printed circuit board. They are used in systems where lower power is required.

BMS Research and Development (R&D)

Advanced Algorithm Development

We design custom BMS algorithms for different battery types and uses. We have a seasoned team to develop algorithms to estimate State of Charge (SOC) and State of Health (SOH). Subsequently, we optimize these algorithms for effective temperature control, cell balancing, and problem detection.

BMS Hardware Design

We create schematic designs and PCB layouts for BMS circuits. Next, our team chooses and tests components to ensure strong BMS performance. Our designs cover different BMS setups like centralized, distributed, and modular systems.

BMS Software and Firmware Development

We develop embedded software for BMS microcontrollers. Later, our experts integrate Real-time Operating Systems (RTOS) for BMS applications. In the final step, we create communication protocols such as CAN, SPI, and I2C for BMS data sharing.

Prototyping and Validation

We quickly prototype BMS designs for the fundamental testing and concept proof. For instance, our experts perform functional tests to validate BMS prototypes. Subsequently, we conduct environmental and EMC/EMI tests to guarantee BMS dependability.

BMS Manufacturing

High-Quality PCB Manufacturing for BMS

Our company is specialized in PCB fabrication for BMS, including complex PCBs with multiple layers and impedance control. Moreover, we give high-priority to quality checks. Our PCB manufacturing follows industry standards like IPC.

BMS PCBA (PCB Assembly) Services

We offer automated SMT and through-hole assembly for BMS parts. Our skilled team is experienced in handling delicate BMS components. For example, we incorporate In-Circuit Testing (ICT) and functional testing during assembly.

Supply Chain Management

We manage component sourcing and purchasing for BMS manufacturing. This include handling inventory to ensure on-time production and delivery. We partner with trusted component suppliers to maintain quality and cost efficiency.

Scalable Production

Our manufacturing is flexible to support quick prototypes, small orders, and large-scale BMS production. Our production process is efficient and effortlessly meets customer volume needs and schedules.

BMS Testing and Validation

Comprehensive BMS Testing

We conduct functional testing to check BMS performance against set specifications. Moreover, environmental tests (temperature, humidity, vibration) are also crucial to test BMS performance. In safety testing, we ensure BMS meets safety standards like UL and IEC.

Performance and Reliability Testing

Battery cycling and aging tests are also decisive for us. Our purpose is to assess long-term BMS performance. Cell balancing and thermal management testing helps optimize battery life along with its safety.

Custom Test Development

Specific test methods and setups based on unique BMS needs are also essential. Automated test systems are effective and consistent BMS testing. We provide detailed test reports and analysis through data logging.

DFM/DFA Analysis

Our company has a separate Design for Manufacturing (DFM) analysis to improve BMS design. For example, Design for Assembly (DFA) analysis helps simplify BMS assembly. Similarly, we provide proactive feedback to clients for design customization and cost savings.

BMS Testing and Validation

BMS Consulting and Design Support

Our professional team will give you their expert advice to select BMS, design, and its integration following your requirements. Furthermore, you can enjoy our technical support throughout your BMS development. Our team will be working with your engineers to create the best BMS solutions.

Custom BMS Solutions

We develop and manufacture BMS tailored to your unique requirements. We provide adaptable BMS designs and features based on how you will use them. We integrate BMS with other system parts like power electronics and communication systems.

After-Sales Support and Maintenance

Our customers will also enjoy technical support for BMS integration and operation. For instance, we offer troubleshooting and maintenance advice. Subsequently, our company can potentially offer remote BMS monitoring and diagnostic services.

Industry

what makes us different

Why Choose HUANG TE PCB for BMS Services?

Complete BMS Solutions

We offer end-to-end BMS services. It covers everything from research and development to manufacturing and rigorous testing.

Specialized PCB Manufacturing

Our company offers expert PCB manufacturing for BMS applications.

Tailored BMS Solutions

We provide custom BMS solutions. Every solution is designed to meet your exact requirements.

Experienced BMS Engineering Team

Our team has extensive knowledge and experience in Battery Management Systems.

Advanced Facilities

We utilize state-of-the-art manufacturing and testing facilities for BMS production.