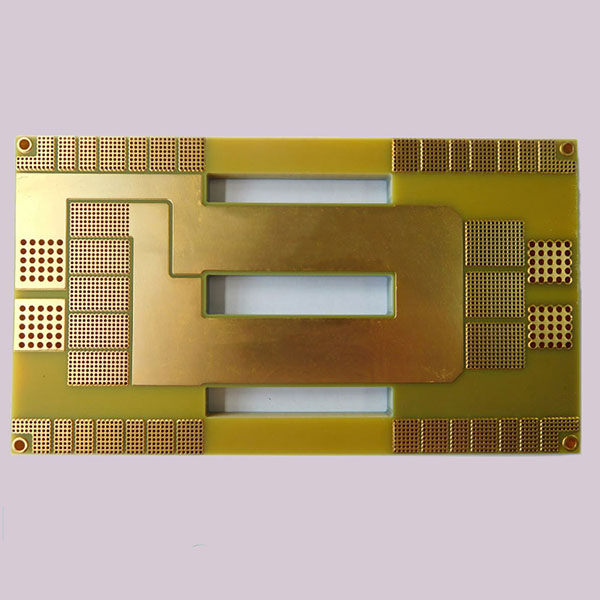

Heavy Copper PCB

Thick copper PCB refers to a printed circuit board (PCB) whose copper foil thickness reaches a certain standard. Generally speaking, when the finished copper thickness is ≥2oz, it can be defined as a thick copper PCB.

Thick copper PCBs have a significant increase in copper foil thickness compared to regular PCBs. The copper foil thickness of conventional PCB is usually between tens to hundreds of microns, such as 18μm, 35μm, etc. The copper foil thickness of thick copper PCB is much thicker, with 3oz, 4oz or even higher being common.

This increase in thickness makes thick copper PCBs perform very differently than regular PCBs. First, thick copper PCBs are more conductive and can carry larger currents, making them suitable for high-power electronic devices. Secondly, the heat dissipation performance of thick copper PCB is also better, which can effectively dissipate the heat generated during work and ensure the stable operation of electronic equipment.

In terms of manufacturing process, thick copper PCB is also more complex and requires special processing, such as etching, electroplating, etc., to ensure the uniformity and conductive properties of the copper layer. At the same time, due to the thick copper layer, thick copper PCBs also need to be careful to avoid deformation during processing and maintain the flatness and stability of the PCB.

Feature of Heavy Copper PCB

Thick copper PCB has excellent heat dissipation performance, which is mainly due to its thick copper layer. Copper itself has good thermal conductivity. The thick copper layer can quickly absorb the heat generated by electronic components when they are working and quickly conduct it to the surrounding environment. In high-power electronic devices, heat generation is relatively concentrated and large in quantity. Thick copper PCB can effectively disperse the heat to avoid local overheating, thereby ensuring the stable operation of electronic equipment. For example, in the fields of power modules and automotive electronic components, thick copper PCB can ensure that the operating temperature of the equipment is still within a controllable range under long-term high-load working conditions, effectively extending the service life of electronic equipment.

Heavy copper PCB application

Power electronics

Thick copper PCBs can withstand higher current and power, so they are widely used in power electronics. For example, power modules, inverters, frequency converters, etc.

High-frequency electronics

Thick copper PCBs have lower resistance and inductance, and can provide better high-frequency performance. Therefore, thick copper PCBs are often used in high-frequency electronic devices such as RF communication equipment, radar systems, and microwave equipment.

Automotive electronics

Automotive electronic equipment usually needs to withstand higher temperatures and currents, so PCBs with good heat dissipation performance are required. Thick copper PCBs can meet these requirements, so they are widely used in the automotive electronics field. For example, engine control modules, electric vehicle chargers, etc.

LED lighting

LED lighting products usually require higher current and heat dissipation performance. Thick copper PCBs can provide good heat dissipation performance, so they are widely used in LED lighting products. For example, LED light bars, LED lamp beads, etc.