High-Performance HDI PCB Manufacturing

Advanced solutions for compact, high-speed, and reliable electronics.

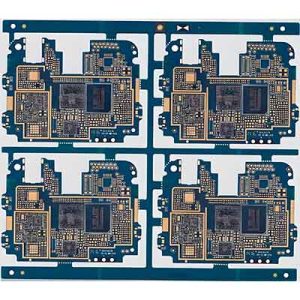

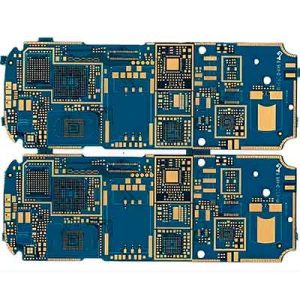

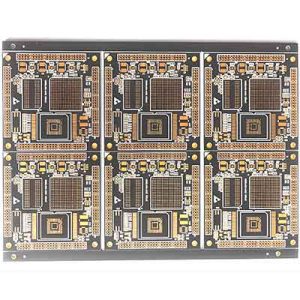

At HUANG TE PCB, we specialize in manufacturing High Density Interconnect (HDI) PCBs with precise multilayer structures, microvia technology, and advanced materials to meet the demands of modern electronic products.

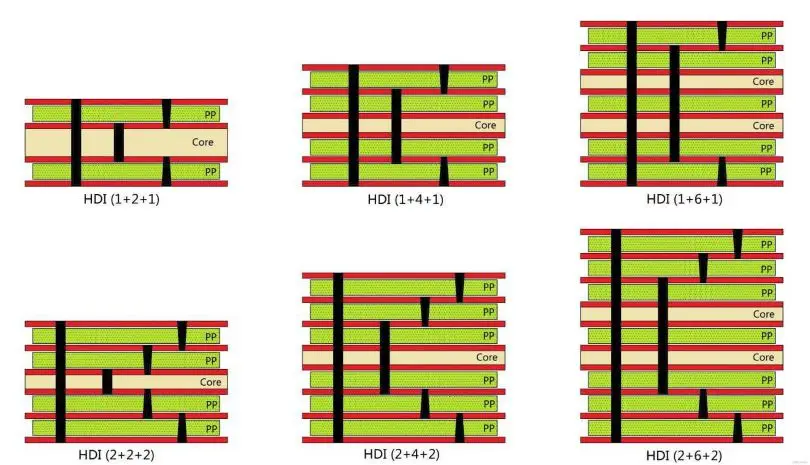

Common Buildup Structure

The difference between HDI PCB and ordinary PCB, you can see from the Buildup Structure.

The Stackup show 1+ N +1 and 2+N+2 HDI PCB Structure

HDI PCB vs. Traditional PCB

| Feature / Parameter | HDI PCB (High Density Interconnect) | Traditional PCB |

|---|---|---|

| Line/Space | As low as 50 μm (0.05 mm) | Typically ≥ 100 μm |

| Via Technology | Microvias, blind vias, buried vias, via-in-pad | Through-hole vias only |

| Layer Count | Up to 20+ layers with compact design | Usually up to 8–12 layers |

| Density | High component density, compact design | Lower density, larger board size |

| Signal Integrity | Better performance for high-speed & RF circuits | More signal loss and crosstalk |

| Size & Weight | Smaller, lighter, space-saving | Larger and heavier |

| Design Flexibility | Allows advanced stack-ups (1+N+1, 2+N+2, any-layer) | Limited stack-up options |

| Applications | Smartphones, tablets, medical devices, automotive, aerospace | Consumer electronics, industrial equipment, home appliances |

| Manufacturing Cost | Higher (advanced process required) | Lower |

| Reliability | High reliability, especially for portable and high-frequency devices | Standard reliability |

Over 30 years of PCB manufacturing experience

Advanced HDI production lines with strict quality control

In-house testing & reliability verification (X-ray, AOI, impedance test, etc.)

Fast prototyping & mass production services

Strong engineering team supporting DFM (Design for Manufacturability)

Laser-drilled microvias (blind & buried)

1+N+1, 2+N+2, and any-layer HDI stack-up options

Minimum line/space: 50 μm

Via-in-pad & filled via technology

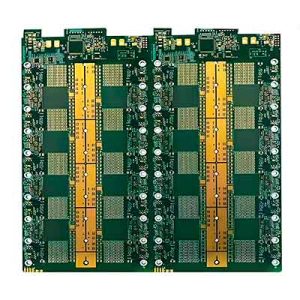

High layer count (up to 20+ layers)

Advanced surface finishes (ENIG, Immersion Silver, Hard Gold, etc.)

Reliable material options: Rogers, Panasonic, Isola, etc.

HDI PCBs bring multiple benefits compared to standard PCBs, including:

Higher component density for compact design

Improved signal integrity & reduced crosstalk

Enhanced electrical performance for high-speed circuits

Lightweight and space-saving for portable devices

Greater design flexibility

Our HDI PCBs are widely used in:

Smartphones & tablets

Automotive electronics & ADAS systems

Medical devices & wearable technology

Network & communication equipment

Consumer electronics

Aerospace & defense systems

Multi-Layer PCB Manufacturing Capability