Flexible PCB Manufacturer

HUANG TE PCB provides Flexible PCB(FPC) Prototype, Manufacturing, and Assembly Services.

- NO MOQ: 1 pcs to do

- FPC Manufacturing and Assembly Services

- FPC Thickness:0.05 mm-1.0 mm

- Delivery in 48 Hours at the earliest

- Direct Manufacturing Factory Price

- Free Prototype before Mass Production

services

Advantages of FPC

Flexibility

FPCBs can be bent, twisted, and folded without compromising their performance. This makes them ideal for use in compact and curved devices, allowing for more versatile designs.

Lightweight and Thin

Flexible PCBs are typically thinner and lighter than traditional rigid PCBs, which helps reduce the overall weight and size of the end product, making them suitable for space-constrained applications.

Cost-Efficient for Complex Designs

Flexible PCBs can replace multiple rigid PCBs, connectors, and wires, leading to a reduction in assembly costs and errors. They simplify manufacturing and improve the overall design, especially in applications with intricate circuit layouts.

services

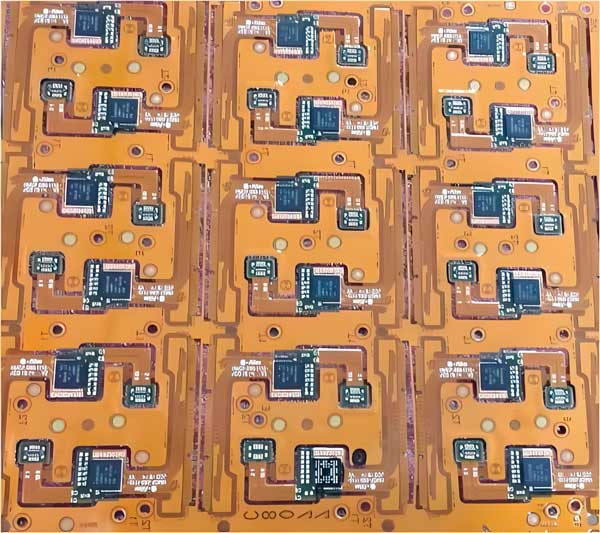

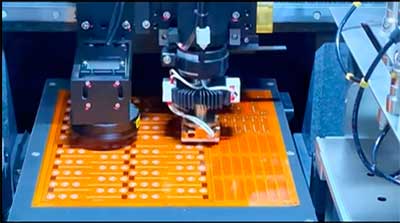

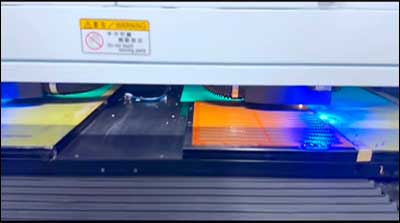

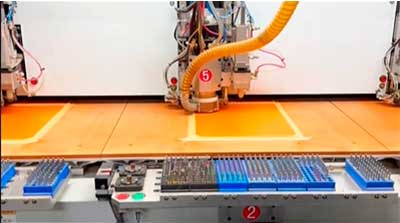

FPC Assembly

Our Flexible PCB Assembly service offers end-to-end solutions, including assembly and testing, ensuring high precision, reliability, and customized solutions to meet specific client requirements.

Manufacturing and Assembly(THT&SMT)

Electronic Components Sourcing

Testing

Final Inspection and Quality Control

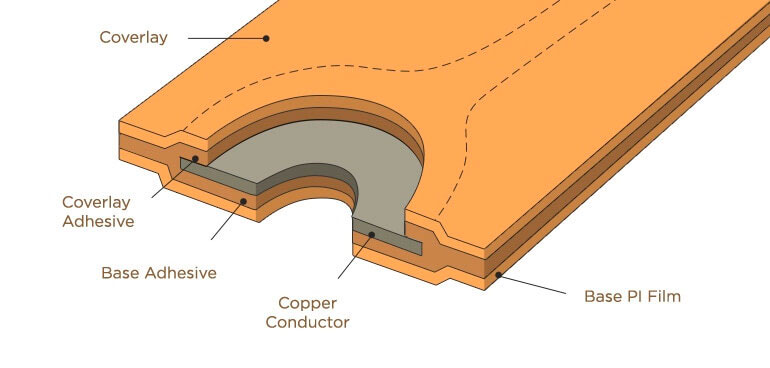

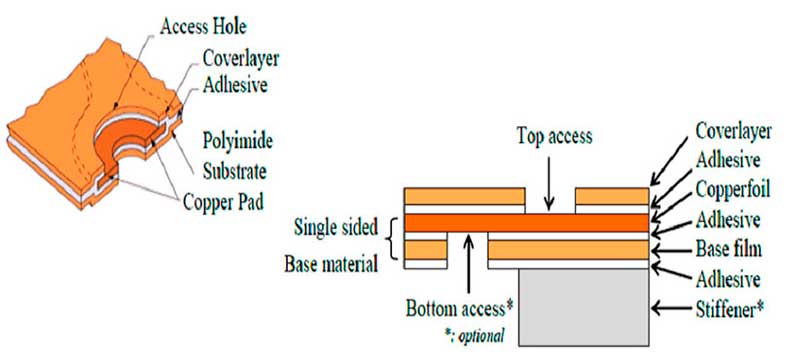

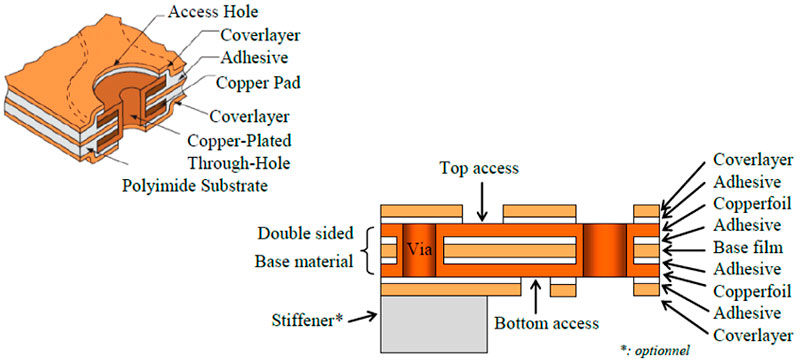

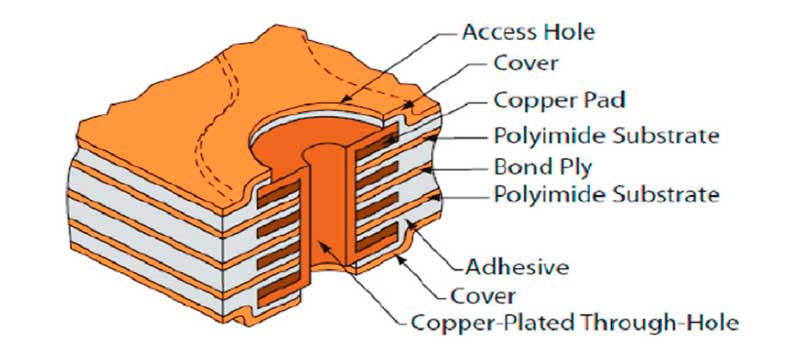

The Stackup of Common Flexible PCB

Single Sided Flexible PCB with Dual Access

Double Sided Flexible PCB Structure

Multi-Layer Flexible PCB Structure

Typical Material of Flexible Printed Circuit

| Material for flexible PCBs | Recommended max. operating temperature | Copper type | Tg | Ԑr, Dk- Permittivity | CTE-z (T<Tg) | Electric Strength | Surface resistivity | Peel strength |

|---|---|---|---|---|---|---|---|---|

| °C | * | °C | @1MHz | ppm/°C | KV/mm | MΩ | N/mm | |

| Polyimide + Adhesive | ||||||||

| Shengyi SF305 | 105° | Rolled Copper | – | 3,6 | 21 | – | 1 x 10^5 | 1,1 |

| Polyimide | ||||||||

| DuPont Pyralux AP | 180° | Rolled Copper | 220 | 3,4 | 25 | 256 | 1 x 10^10 | 1.8 |

| Panasonic RF775 | 130° | Electrolytically Deposited Coppe | 343 | 3,2 | – | 276 | 1 x 10^8 | 1,7 |

| Thinflex W-05050 | 105° | Electrolytically Deposited Coppe | 350 | 3,3 | 24 | 216 | 1 x 10^5 | 0.6 |

| PI Coverlay | ||||||||

| 105° | – | – | – | – | – | 3 x 10^6 | – | |

| DuPont Pyralux FR | 180° | – | – | 3.5 | – | 138 | 1 x 10^7 | – |

| Adhesive tape | ||||||||

| 3M 9077 | 150° | – | – | – | – | – | – | – |

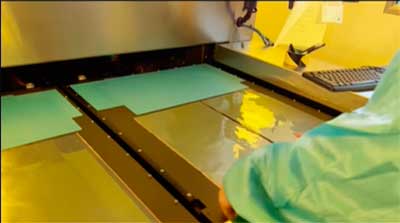

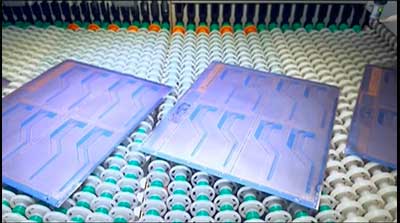

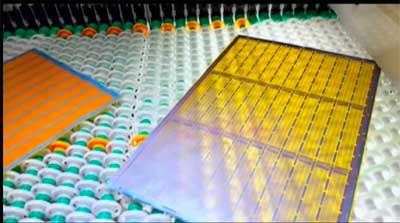

FPC Manufacturing Process and Workshop in Factory

HUANG TE PCB's Flexible PCB Manufacturing Capability

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 1 – 12 layers |

| Order Quantity | 1pc – 100,000+pcs |

| Build Time | 2days – 5weeks |

| Material | Polymide, LCP, PET |

| Material Brand | Shengyi, ITEQ, Taiflex, Thinflex, Allstar, Panasonic, Dupont, Jujiang |

| Stiffener Type | FR4, PI, PET, Steel, Aluminium, PSA, Nylon |

| Board Size | Min 6*6mm, Max 500*2200mm |

| Board Thickness | 0.04 mm – 0.8 mm |

| Copper Weight (Finished) | 0.5oz – 5.0oz |

| Min Tracing/Spacing | 0.030 mm/0.030 mm |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating—Soldermask oil | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating—Coverlay | PI and PET film |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | ENIG, ENEPIG, OSP, Gold Plating, Gold Plating+ENIG, Gold Plating+OSP, Immersion Silver, Immersion Tin, Plating Tin |

| Min Drilling Hole Diameter | Mechanical Drilled:0.1 mm; Laser Drilled: 0.025 mm; |

| Min. hole size—Drilling (PTH) | 0.2mil |

| Min. hole size—Punching (NPTH) | 0.5mil |

| Tolerance of dimension | ±0.05mm |

| Min Annular Ring of Single/Double-sided Board | 3 mil |

| Min Inner Layer Annular Ring of Multi-layer Board | 4 mil |

| Min Outer Layer Annular Ring of Multi-layer Board | 4 mil |

| Min Coverlay Bridge | 4 mil |

| Min Solder mask Opening | 6 mil |

| Min Coverlay Opening | 0.30 mm x 0.30 mm |

| Min BGA Pitch | 0.045 mm |

| Min Single-ended Impedance Tolerance | >= 7% |

| Min Differential Impedance Tolerance | >= 7% |

| Other Techniques | Peelable solder mask; Gold fingers; |

What people say

Robert Wilson

HUANG TE PCB’s flexible PCBs have consistently met our high standards. Their manufacturing process is smooth and reliable, ensuring we receive top-quality products every time without delays.”

Miley Henry

The engineering support we’ve received from HUANG TE PCB has been invaluable. They guided us through every step of the production process, ensuring that our flexible PCBs were designed and manufactured exactly as needed.