Chip Analysis & Component Verification: Protecting Electronic Devices Manufacturers

Focus Keyphrase: Circuit Board Components

Secondary Keywords: Electronic Devices Manufacturers, IC Board Components, Printed Circuit Manufacturer, Parts of a PCB.

The Firewall for Your Supply Chain

In the current global market, Electronic Devices Manufacturers face a hidden threat: the reliability of their supply chain. A single counterfeit chip can cause a field failure that destroys a brand’s reputation.

CtrlcPCB provides more than just manufacturing; we offer a defensive shield. Our Chip Analysis services are designed to verify the authenticity and integrity of critical Circuit Board Components before they are soldered onto your boards.

When Do You Need Component Verification?

You don’t need to analyze every resistor, but you must validate the brain of your device.

Critical Scenarios:

-

Supply Chain Validation: You sourced IC Board Components from a broker instead of a franchised distributor. Are they genuine?

-

Legacy Product Support: You are buying obsolete Parts of a PCB from the grey market to keep an old line running.

-

Inconsistent Performance: A batch of boards is failing, and you suspect the Circuit Board Components are re-marked or below spec.

Our Engineering Assessment Methodology

As a veteran Printed Circuit Manufacturer, we know exactly what a good chip looks like—inside and out.

1. External & Surface Inspection

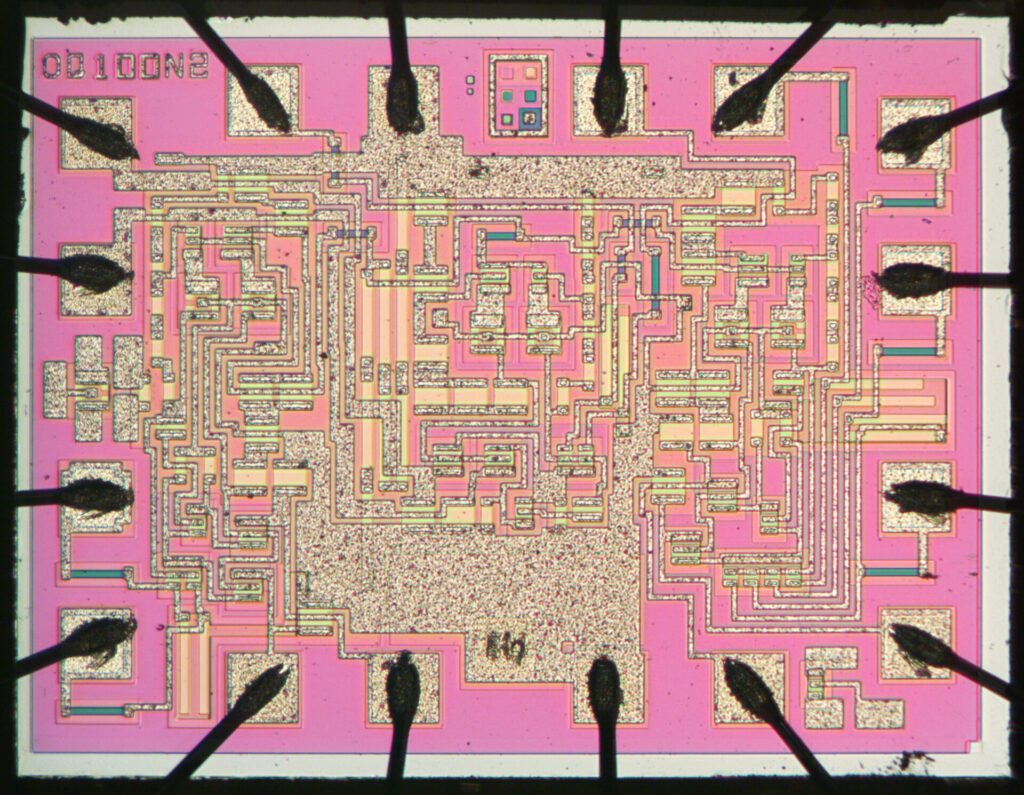

We start by examining the Circuit Board Components under high-magnification microscopes. We look for:

-

Sanding Marks: Evidence that the original part number was scrubbed off.

-

Blacktopping: New epoxy painted over the old surface to hide the original identity of IC Board Components.

-

Lead Condition: Oxidation or re-tinning signs indicating used/pulled parts.

2. Internal Structure Verification

Using X-Ray and decapsulation, we look inside the package.

-

Die Marking Check: We expose the silicon die to read the manufacturer’s logo and copyright year. This is the ultimate truth test for any Circuit Board Components.

-

Wire Bonding: Checking if the internal construction matches the “Golden Sample” from the original datasheet.

Compliance & Authorized Application

We help Electronic Devices Manufacturers stay safe and compliant.

-

Legitimate Use: Our services are strictly for quality control, failure analysis, and parts of a PCB verification.

-

Authorization: We require customers to confirm the source and ownership of the components being analyzed.

-

No IP Theft: We verify authenticity; we do not extract firmware for cloning purposes under this service.

Why Partner with a Manufacturer?

Third-party labs can give you a report, but they don’t understand the assembly context.

As a Printed Circuit Manufacturer, we understand how these IC Board Components interact with the rest of the board. We provide engineering insights, not just images.

Secure Your Production Line.

Don’t let a $1 chip ruin a $1000 device. Let us verify your critical components.