Ceramic PCB

HUANG TE PCB specializes in Ceramic PCB Manufacturing, providing high-quality, high-performance ceramic circuit board solutions. Due to their excellent thermal conductivity, electrical insulation properties, and stable mechanical characteristics, ceramic PCBs are widely used in industries such as high-power electronics, communication, automotive, medical, and LED lighting.

List the Kinds of Ceramic PCB that we can fabrication

Thick Film Ceramic PCB

Thin Film Ceramic PCB

DPC Ceramic PCB

DBC Ceramic PCB

LTCC PCB

HTCC PCB

AMB Ceramic PCB

services

What is Ceramic PCB?

Ceramic PCBs, or ceramic printed circuit boards, represent a specialized category of PCBs that utilize ceramic materials as their substrate. Unlike traditional PCBs, which often employ materials like FR4 (a composite of fiberglass and epoxy resin), ceramic PCBs are designed to meet the demands of high-performance applications. The use of ceramics in PCBs is not a recent innovation; it has evolved over decades, driven by the need for materials that can withstand higher temperatures and offer superior electrical insulation.

Historically, the development of ceramic PCBs can be traced back to the growing demands of the electronics industry for more robust and reliable materials. As electronic devices became more compact and powerful, the limitations of conventional PCB materials became apparent, particularly in terms of thermal management and electrical performance. This led to the adoption of ceramics, known for their excellent thermal conductivity and stability, as a viable alternative.

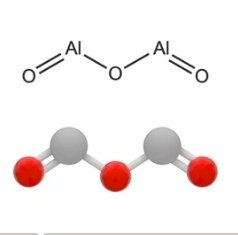

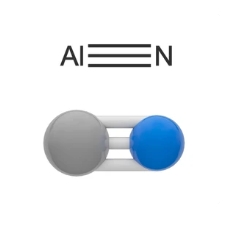

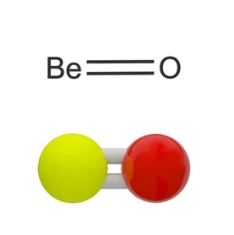

Materials Used in Ceramic PCBs

Ceramic PCBs are primarily composed of materials such as alumina (Al2O3), aluminum nitride (AlN), and beryllium oxide (BeO). Each of these materials offers distinct properties that make them suitable for specific applications:

These materials are chosen based on the specific requirements of the application, balancing factors such as thermal performance, electrical insulation, and cost.

services

Ceramic PCB

Ceramic PCBs offer several advantages over traditional PCBs, making them ideal for high-performance applications:

Thermal Conductivity

Ceramic materials provide excellent thermal conductivity, allowing for efficient heat dissipation and reducing the risk of overheating.

Electrical Insulation

Ceramics offer superior electrical insulation, minimizing the risk of short circuits and enhancing device reliability.

Durability and Stability

Ceramic PCBs are highly durable and stable, capable of withstanding harsh environmental conditions and high temperatures.

Applications of Ceramic Substrate PCB

Ceramic PCBs are used across various industries and sectors, including:

Automotive: Used in engine control units and LED lighting systems due to their thermal management capabilities.

Aerospace: Employed in avionics and satellite systems where reliability and performance are critical.

Medical Devices: Utilized in imaging equipment and implantable devices for their biocompatibility and stability.

Telecommunications: Applied in high-frequency communication devices for their excellent electrical properties.

Challenges and Drawbacks of Ceramic Substrate PCB

Despite their advantages, ceramic PCBs also present certain challenges:

Cost Considerations: The materials and manufacturing processes for ceramic PCBs are generally more expensive than traditional PCBs.

Manufacturing Complexities: The production of ceramic PCBs involves complex processes that require specialized equipment and expertise.